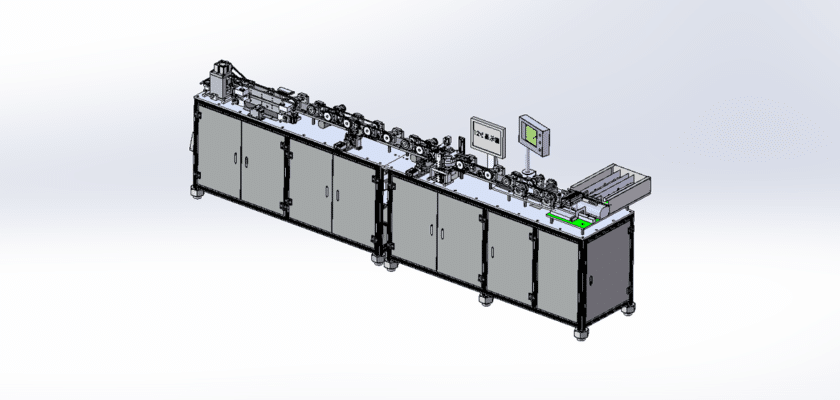

A Resistor Component Inspection Line Drawing is a technical illustration that outlines the layout and components of a production line dedicated to the inspection of resistor components. This drawing is essential for ensuring quality control and operational efficiency in manufacturing processes.

Ключевые особенности:

- Inspection Stations: Diagrams showing multiple stations along the inspection line where resistors are evaluated, each equipped with fixtures or holders to secure the components during testing.

- Automatic Feed System: Representation of the conveyor or automated transport system that moves resistors from one inspection station to the next, ensuring a continuous flow of parts.

- Testing Equipment: Details about the measurement devices used to evaluate resistor parameters, such as resistance value, tolerance, and thermal performance, including multimeters or specialized testing rigs.

- Control Unit: Information on the central processing unit that manages the inspection workflow, records measurements, and analyzes data for quality assurance.

- User Interface: Illustrations of the control panel or touchscreen that allow operators to monitor the inspection process, set parameters for testing, and view real-time results.

- Data Output Systems: Diagrams showing how inspection results are logged and communicated, including digital displays for immediate feedback, data storage systems for analysis, and connections for external reporting.

- Mechanical Framework: Information about the structural components that provide support and stability to the inspection line, ensuring precise operation and minimal vibration.

- Power Supply: Details regarding the power requirements, including electrical connections and any backup systems to ensure reliable operation.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of resistor component inspection lines, ensuring high standards of quality control and efficiency in manufacturing processes.