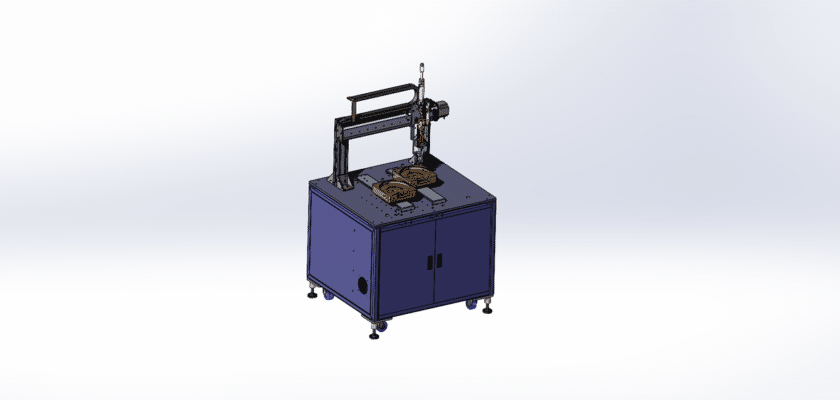

Трёхкоординатный винтовой станок с пневмоприводом — это передовое автоматизированное решение, предназначенное для точной сборки винтов в различных производственных условиях. В станке используется технология пневмопривода, которая обеспечивает быструю обработку и установку винтов, обеспечивая высокую эффективность и точность производственных процессов.

Ключевые особенности

- Управление движением по трем осям: обеспечивает гибкое перемещение по трем осям (X, Y и Z), что позволяет точно позиционировать и выравнивать винты при выполнении сложных сборочных задач.

- Технология продувки воздухом: использует целенаправленный механизм продувки воздухом для надежного позиционирования и направления винтов на место, сводя к минимуму риск смещения и повышая производительность.

- Высокоскоростная работа: Способен сокращать время цикла, значительно увеличивая производительность без ущерба для качества.

- Дизайн, ориентированный на пользователя: имеет простой в использовании интерфейс с программируемыми настройками для различных типов и размеров винтов, что упрощает процесс настройки.

- Компактный и легкий: Разработан таким образом, чтобы занимать минимальную площадь и при этом быть удобным для транспортировки в пределах производственной зоны.

Приложения

- Сборка электроники: Идеально подходит для крепления компонентов в электронных устройствах, где точность и скорость имеют первостепенное значение.

- Автомобильное производство: Подходит для различных применений на линиях сборки автомобилей, повышая скорость и точность сборки.

- Общее производство: Достаточно универсален для использования в широком спектре отраслей, требующих эффективных крепежных решений.

Технические характеристики

- Источник питания: [Укажите требования к напряжению и мощности]

- Требования к давлению воздуха: [Укажите диапазон давления воздуха]

- Размеры: [Укажите размеры машины]

- Масса: [Укажите вес]

Заключение

Трёхкоординатный винтовой станок с пневмоприводом — это инновационный инструмент, который произвел революцию в процессе сборки винтов. Сочетание передовой технологии пневмопривода и трёхкоординатного управления движением делает его незаменимым инструментом для современного производства, обеспечивая быструю, точную и эффективную работу.