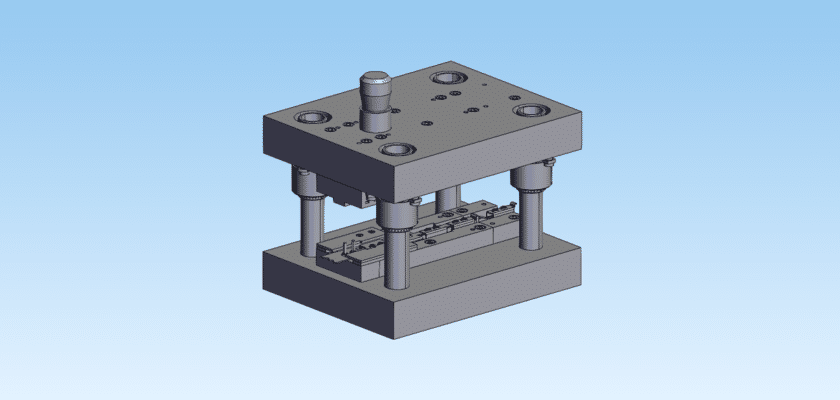

Elevate your fabrication capabilities with our high-precision technical documentation for the Alat Za Oblikovanje Lima. This sheet metal forming tool is the backbone of high-quality metalwork, designed to provide consistent results in bending, punching, and shaping operations. Whether you are running a custom fabrication shop or a high-volume automotive production line, having the correct tool geometry is vital for minimizing material springback and ensuring dimensional accuracy across every batch.

The included чертеж files offer an in-depth look at the punch and die clearances, as well as the specialized heat-treatment zones required for industrial-grade tooling. By utilizing these professional blueprints, engineers can analyze the stress distribution during the forming process, allowing for the creation of components with superior structural integrity. We provide these resources for free to help you reduce prototyping time and move straight into the manufacturing phase with confidence.

Our CAD assets are compatible with all major engineering platforms, making it easy to simulate the forming process before a single piece of steel is cut. This data-driven approach helps in predicting wear patterns and optimizing the tool life cycle. Download this comprehensive drawing package today to streamline your sheet metal production and achieve the perfect finish on your complex metal geometries.

Ключевые особенности:

- Precision Die Clearance: Specifically calculated tolerances to prevent material tearing and burr formation.

- Modular Insert Design: Features interchangeable components for easy maintenance and versatile forming shapes.

- High-Wear Resistance: Designed for integration with D2 or SKD11 tool steel specifications for longevity.

- Optimized Pressure Distribution: Engineered to provide uniform force across the workpiece to prevent warping.

- Universal Shank Compatibility: Designed to fit standard press brakes and punch press machinery with ease.