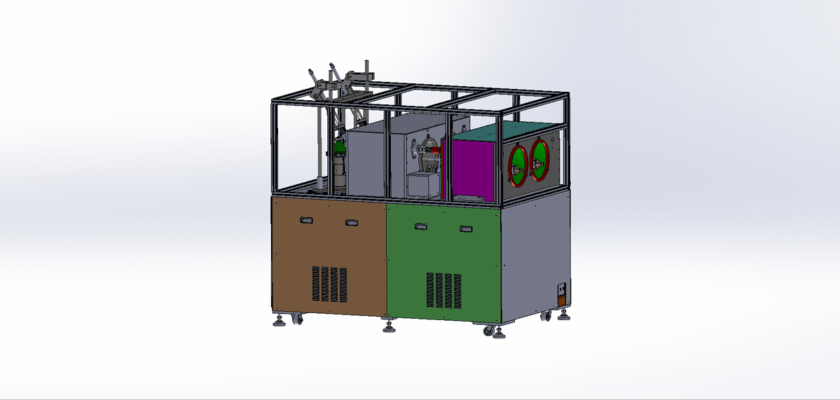

Откройте для себя мир высокоскоростного производства с помощью нашего бесплатного чертежа автоматизированного намоточного станка. Это специализированное оборудование является краеугольным камнем таких отраслей, как электроника, текстильная промышленность и производство катушек, и разработано для… намотать проволоку, нить или волокно на катушку или сердечник с непревзойденной скоростью и точностью. Автоматизируя этот процесс, он обеспечивает равномерное натяжение, точное наложение слоев и идеальную намотку готового изделия. Этот подробный чертеж — бесценный ресурс для инженеров, производителей и студентов, желающих понять сложную механику и принципы автоматизации, лежащие в основе этого важнейшего производственного инструмента.

Наш подробный чертеж наглядно демонстрирует основные компоненты механизма: прочную раму, прецизионный намоточный шпиндель, автоматизированную систему натяжения и механизм перемещения для равномерной намотки. Вы получите глубокое понимание того, как эти элементы работают в идеальной синхронизации, гарантируя, что каждая катушка или бобина намотана точно в соответствии с заданными параметрами. Независимо от того, являетесь ли вы профессионалом, проектирующим новую производственную линию, студентом, изучающим мехатронику, или любителем, собирающим прототип, этот чертеж даст вам необходимые базовые знания. Скачайте его бесплатно и сделайте первый шаг к более интеллектуальной и эффективной намотке.

Ключевые особенности

- Автоматизированный контроль натяжения: В проекте представлена система, которая автоматически регулирует натяжение проволоки по мере намотки, обеспечивая получение готового продукта стабильно высокого качества.

- Механизм прецизионного перемещения: Узнайте, как машина использует линейная направляющая и приводная система перемещать точку намотки вперед и назад, обеспечивая равномерную укладку проволоки на катушку.

- Высокоскоростная работа: Машина спроектирована для скорости и эффективности, демонстрируя, как можно достичь высокой производительности при минимальном вмешательстве человека.

- Универсальный дизайн: Конструкция адаптируется к широкому диапазону калибров проволоки и размеров сердечников путем простой замены намоточного шпинделя и направляющих.

- Интегрированная система управления: На рисунке показано, как скорость намотки, натяжение и поперечное движение контролируются центральным контроллером для получения повторяемых результатов.