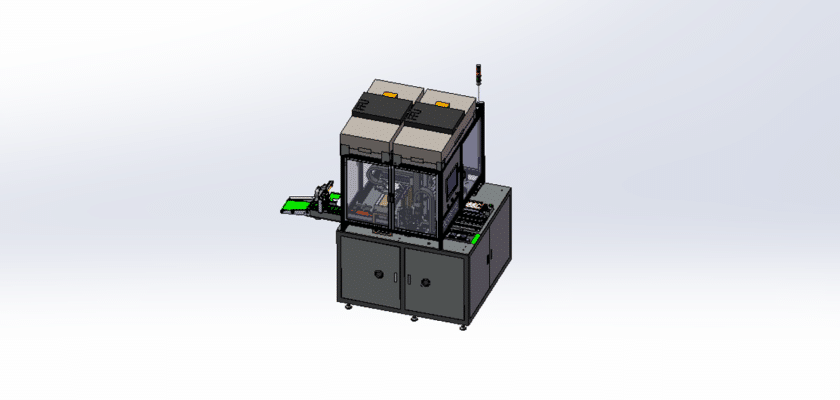

This detailed drawing of the Automatic Assembly Machine for Touch Screens showcases a specialized system designed for the efficient and precise assembly of touch screen components used in various electronic devices. Ideal for manufacturers in the consumer electronics, automotive, and industrial sectors, this machine enhances production efficiency while ensuring high-quality outputs.

Основные особенности рисунка:

- Автоматизированный процесс сборки: The machine employs advanced automation technology to minimize manual intervention, significantly increasing throughput and consistency in the assembly of touch screens.

- Высокоточная обработка: Оснащены точными механизмами для выравнивания и позиционирования компонентов, обеспечивающими точную сборку, соответствующую строгим стандартам качества и производительности.

- Удобный интерфейс управления: The intuitive control panel allows operators to easily program and monitor the assembly process, facilitating quick adjustments for different touch screen sizes and specifications.

- Универсальная совместимость: Designed to accommodate various touch screen designs, including capacitive and resistive types, making it adaptable for diverse applications across multiple industries.

- Интегрированный контроль качества: Features real-time monitoring and inspection systems to ensure that each assembled touch screen meets quality standards, reducing defects and enhancing reliability.

- Прочная и долговечная конструкция: Изготовленная из высококачественных материалов, машина спроектирована для долговечности и надежности, гарантируя оптимальную производительность в сложных производственных условиях.

This drawing serves as a vital resource for engineers and manufacturers seeking to implement effective and efficient assembly solutions for touch screens in their production lines.