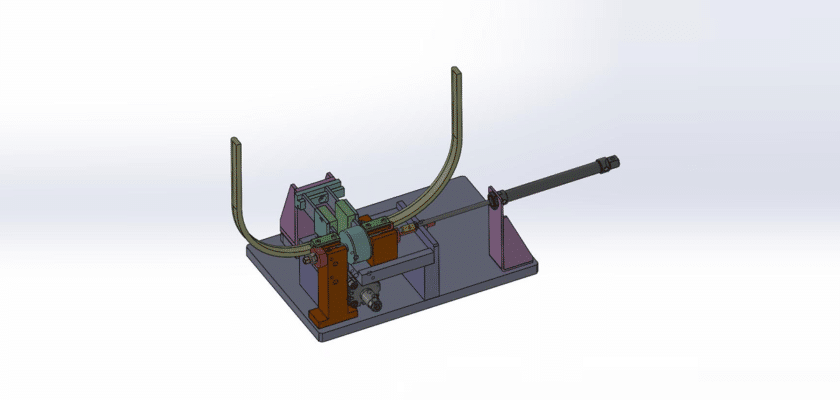

На этом детальном чертеже автоматической сборки стопорных колец ротора представлена специализированная система, предназначенная для эффективной сборки стопорных колец ротора, используемых в различных областях, включая двигатели и генераторы. Эта машина идеально подходит для производителей в автомобильной, аэрокосмической и промышленной отраслях, повышая эффективность производства и обеспечивая высокое качество продукции.

Основные особенности рисунка:

- Автоматизированный процесс сборки: В машине используется передовая технология автоматизации, которая сводит к минимуму ручное вмешательство, что значительно повышает производительность и единообразие при сборке стопорных колец ротора.

- Высокоточное выравнивание: Оснащены точными механизмами для выравнивания и позиционирования компонентов, обеспечивающими точную сборку, соответствующую строгим стандартам качества и производительности.

- Удобный интерфейс управления: Интуитивно понятная панель управления позволяет операторам легко программировать и контролировать процесс сборки, обеспечивая быструю настройку для различных конструкций и спецификаций роторов.

- Универсальная совместимость: разработан для установки стопорных колец ротора различных размеров и конфигураций, что делает его пригодным для разнообразного применения в различных отраслях промышленности.

- Интегрированный контроль качества: Оснащены системами мониторинга и проверки в режиме реального времени, которые гарантируют, что каждое собранное стопорное кольцо соответствует стандартам качества, что снижает количество дефектов и повышает общую надежность.

- Прочная и долговечная конструкция: Изготовленная из высококачественных материалов, машина спроектирована для долговечности и надежности, гарантируя оптимальную производительность в сложных производственных условиях.

Этот чертеж служит важным справочным материалом для инженеров и производителей, стремящихся внедрить эффективные и производительные решения по сборке стопорных колец ротора на своих производственных линиях.