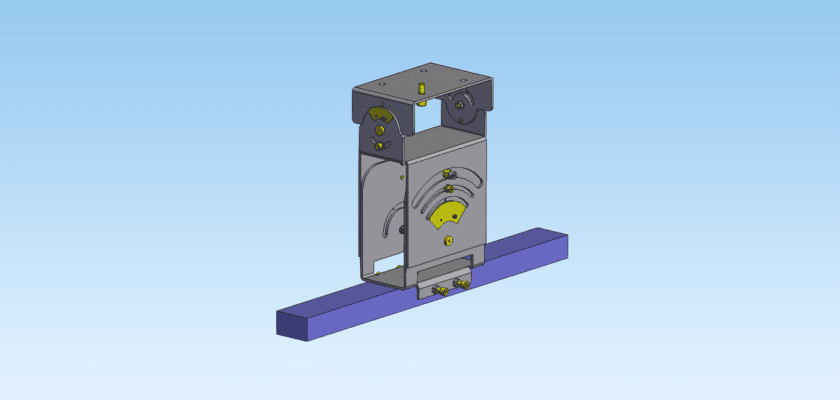

Maintaining the geometric accuracy of a multi-axis machine is impossible without the right reference tools, and this Axis Tilt Verification Fixture drawing provides the blueprint for a professional-grade calibration instrument. Over time, mechanical wear, thermal cycles, or minor collisions can cause a machine’s spindle or table to lose its perfect perpendicularity. This technical drawing details a rigid, high-precision fixture designed to mount dial indicators or electronic probes at specific offsets, allowing technicians to sweep a plane and identify “tilt” or “nod” errors in the X, Y, or Z axes.

The documentation covers the assembly of a high-stability base—often made of stress-relieved tool steel or granite—and the precision-ground arms used to hold measurement sensors. By downloading this blueprint, you gain access to a design that prioritizes “zero-flex” architecture, ensuring that the measurements you take are a true reflection of the machine’s geometry rather than fixture deflection. The layout includes specifications for various spindle taper interfaces (such as BT40, CAT50, or HSK) and adjustable probe mounts for checking squareness across large travel ranges. Whether you are performing a routine annual calibration or diagnosing a sudden drop in part quality, this resource provides the verified tolerances and material callouts required to build a reliable metrology asset.

Utilize this industry-standard reference to understand the mathematics of “tramming” a spindle and the proper use of master squares. At MechStream, we provide the technical assets that ensure your machines remain within micron-level specifications. Download this high-fidelity technical asset today.

Ключевые особенности:

- Сверхжесткая конструкция рамы: Engineered with a high-mass, low-expansion structure to prevent vibration or thermal drift during the measurement process.

- Universal Spindle Interface: Detailed schematics for interchangeable shanks, allowing the fixture to be used across different machine brands and sizes.

- Multi-Probe Mounting Grid: Features a series of precision-bored holes for mounting multiple indicators simultaneously to check parallelism and tilt in one sweep.

- Fine-Adjustment Micrometer Heads: Includes layouts for integrated adjustment screws that allow for the “zeroing” of the fixture against a known master reference.

- Protective Storage Case Layout: Includes dimensions for a foam-lined transit case to protect the fixture’s ground surfaces when not in use.