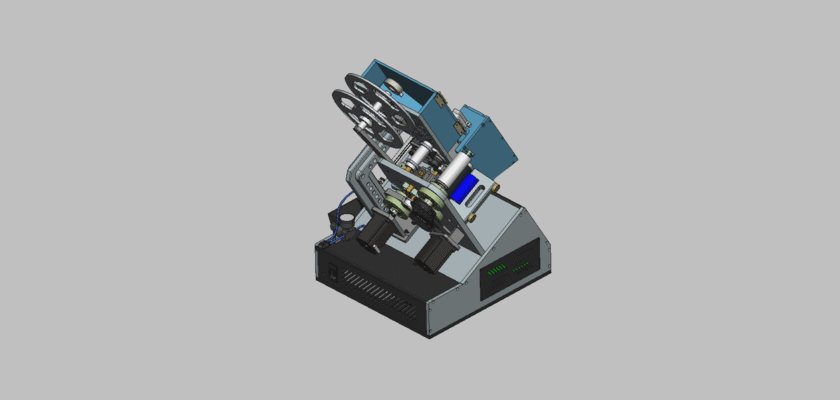

Оптимизируйте свое производство электроники с помощью наших бесплатных технических консультаций. чертеж из Автоматическая машина для обрезки и пожелтения выводов малых конденсаторовЭтот подробный чертеж необходим инженерам, техникам и студентам, специализирующимся на подготовке компонентов для печатных плат (ПП). В современном высокоскоростном производстве выводы конденсаторов должны быть обрезаны до точной длины и обработаны для оптимальной пайки. «Желтение» означает нанесение защитного изолирующего покрытия (часто желтоватой смолы или лака) на выводы – процесс, необходимый для предотвращения коротких замыканий и обеспечения долгосрочной надежности. автоматизированный Машина объединяет эти критически важные этапы в единый эффективный процесс. Загрузив этот чертеж, вы получите глубокое понимание механических и управляющих систем, обеспечивающих возможность высокоточной подготовки компонентов в больших объемах, что позволит вам улучшить свои проекты и оптимизировать сборочные линии.

Ключевые особенности:

- Точная обрезка: В станке используются высококачественные, прочные лезвия для точной обрезки выводов конденсатора до одинаковой длины, что обеспечивает идеальное выравнивание для автоматизированной вставки в печатные платы.

- Интегрированный процесс пожелтения: В чертеже подробно описан специализированный механизм для нанесения точного слоя изоляционной смолы на выводы, что является важнейшим этапом для электроизоляции и защиты.

- Высокоскоростной питатель: Он имеет вибрационный чашевый питатель которая автоматически сортирует и ориентирует конденсаторы большой емкости, доставляя их в зону обработки с высокой скоростью для непрерывного производства.

- Интуитивно понятное управление: Конструкция включает в себя систему управления, как правило, на базе ПЛК, которая позволяет легко регулировать длину выводов и параметры обработки для соответствия различным спецификациям конденсаторов.