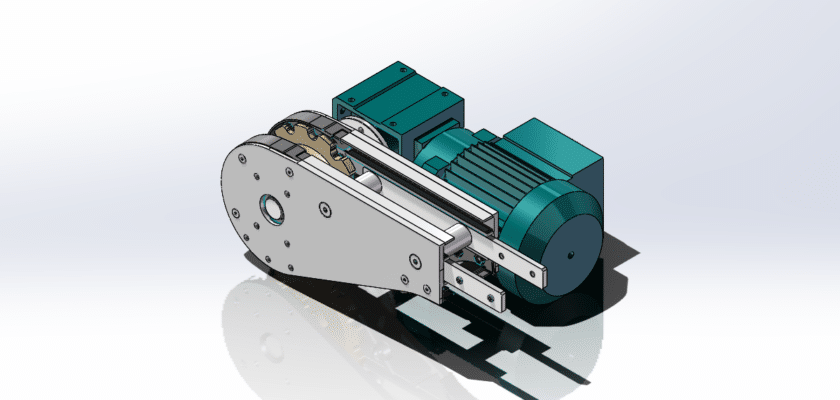

Сайт Чертеж цепного питателя provides a comprehensive visual representation of a chain feeder system designed for the efficient and controlled delivery of materials in various industrial applications. This drawing highlights the key components, structural design, and operational features essential for handling bulk materials such as pellets, grains, or parts.

Ключевые особенности:

- Цепной механизм: The drawing showcases the primary chain drive system, which consists of interconnected links or slats that facilitate the movement of materials. This robust mechanism is designed to handle high loads and provides durability in demanding environments.

- Структура рамы: Illustrated is a sturdy frame typically constructed from high-strength steel or aluminum, ensuring stability and support for the entire feeder system. The frame is engineered to withstand continuous operation and the weight of the materials being fed.

- Узел привода: The drawing includes the drive mechanism, featuring a motor, sprockets, and gear systems that provide the necessary power to move the chain. This assembly is crucial for ensuring consistent feed rates and reliable operation.

- Система натяжения: An adjustable tensioning mechanism is depicted to maintain optimal tension on the chain. Proper tension is critical for preventing slippage and ensuring smooth operation, particularly under varying load conditions.

- Hopper and Feed Chute: The drawing highlights the hopper or feed chute that holds the bulk material before it is fed onto the chain. This component is designed to ensure a steady supply of materials and may include features for controlling flow rates.

- Функции безопасности: The drawing emphasizes essential safety elements such as emergency stop buttons, safety guards, and access points for maintenance. These features ensure a safe working environment and compliance with safety standards.

- Модульная конструкция: The chain feeder is often designed to be modular, allowing for customization and integration into existing production lines. This flexibility enhances its adaptability for various operational requirements.

Приложения:

- Производство: Ideal for transporting components or materials between different stages of production, improving workflow efficiency.

- Переработка пищевых продуктов: Commonly used for feeding bulk ingredients into processing machines while ensuring compliance with hygiene regulations.

- Сельское хозяйство: Suitable for feeding grains, seeds, or feed products in agricultural operations, facilitating efficient material handling.

- Упаковка: Plays a critical role in supplying materials to packaging machines, ensuring a smooth and continuous flow of products.

Общее впечатление:

Сайт Чертеж цепного питателя serves as a vital resource for engineers, designers, and operators involved in the design, implementation, and maintenance of chain feeder systems. By detailing the essential components and their interrelationships, this drawing aids in ensuring efficient and reliable material handling. Understanding this drawing allows stakeholders to make informed decisions regarding the design and functionality of chain feeders tailored to their specific applications, ultimately contributing to improved productivity and operational efficiency across various industrial settings.