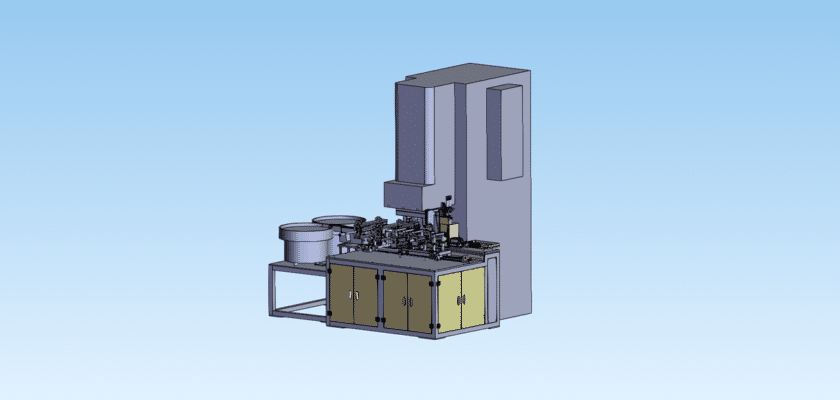

Streamline your factory floor operations with our comprehensive Пуансонный пресс loading and unloading machine CAD resource. In the modern manufacturing landscape, manual material handling is often the biggest bottleneck in high-speed stamping. This professional чертеж provides a detailed blueprint for an automated peripheral system designed to feed raw blanks into the press and remove finished parts with surgical precision. By integrating this machine into your workflow, you can significantly increase strokes per minute while enhancing operator safety by removing the need for manual intervention near the die area.

This download offers a deep dive into the mechanical synchronization between the press stroke and the transfer arms. The layout includes specifications for vacuum suction cups or magnetic grippers, high-speed linear rails, and the pneumatic control systems required for rapid, repetitive motion. By studying this чертеж, engineers can analyze the timing sequences and sensor placements that prevent collisions between the automation hardware and the moving die. Whether you are retrofitting an existing mechanical press or designing a new automated cell, this blueprint provides the structural and kinematic details necessary to build a reliable material handling solution. At MechStream, we are committed to providing these high-value automation assets for free to help you achieve a truly “lights-out” manufacturing environment.

Ключевые особенности:

- Synchronized Transfer Logic: Detailed timing diagrams for coordinating the loader arm movement with the press ram position.

- Modular Gripper Interface: Features a flexible mounting plate for switching between vacuum, magnetic, or mechanical clamping systems.

- High-Speed Linear Actuation: Specifications for precision rails and drive belts designed for low-vibration, high-acceleration movement.

- Double-Sheet Detection: Integrated sensor mounting points to identify and reject stuck sheets before they enter the die.

- Adjustable Stroke Parameters: Designed to accommodate various sheet sizes and press bed heights through a telescopic arm assembly.