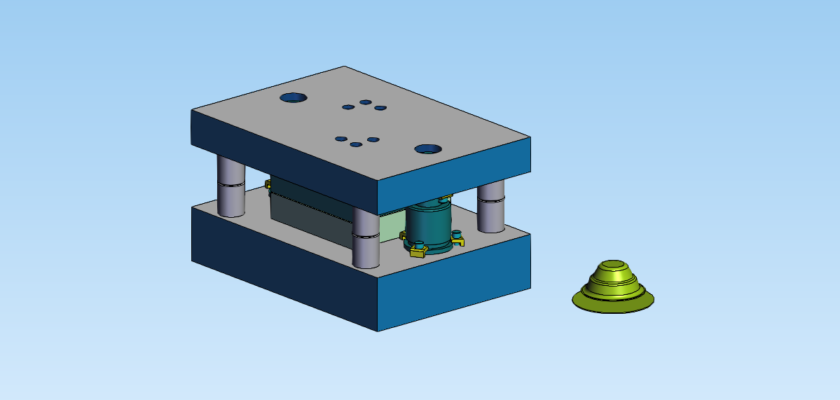

Master the art of sheet metal deformation with our comprehensive technical documentation for Draw Tool Practice. Deep drawing is one of the most challenging processes in the tool and die industry, requiring a perfect balance between material flow and mechanical retention. This drawing package is specifically designed as a reference for engineers and toolmakers to practice the fundamentals of radial flow, blank holder pressure, and punch radius optimization. By utilizing these professional schematics, you can simulate how flat sheet metal transforms into a hollow, three-dimensional shape without wrinkling or fracturing.

The provided чертеж files offer an exhaustive look at the critical geometry of the draw bead, the polished die entry radius, and the air venting required to prevent vacuum buildup during the stroke. By analyzing the clearance ratios between the punch and the die through these blueprints, engineers can gain practical insight into how various materials—such as stainless steel or aluminum—respond to extreme tensile stress. We offer these high-fidelity CAD resources for free to support the technical development of the next generation of manufacturing experts.

Our files are compatible with all major engineering platforms, making it an ideal asset for FEA (Finite Element Analysis) training. You can use these models to test various friction coefficients and lubrication strategies in a virtual environment before moving to the shop floor. Download this essential practice resource today to refine your understanding of metal flow and improve your success rate in complex forming projects.

Ключевые особенности:

- Optimized Draw Radius: Precision-engineered entry curves designed to facilitate smooth material flow and minimize thinning.

- Integrated Blank Holder Design: Detailed layouts for pressure pads to control material intake and prevent flange wrinkling.

- Polished Friction Surfaces: Specifications for surface finishes to reduce heat generation and prevent material galling.

- Standardized Air Venting: Features internal pathways to ensure consistent atmospheric pressure during high-speed forming cycles.

- Modular Practice Inserts: Designed for easy modification, allowing users to test different clearances and bead geometries.