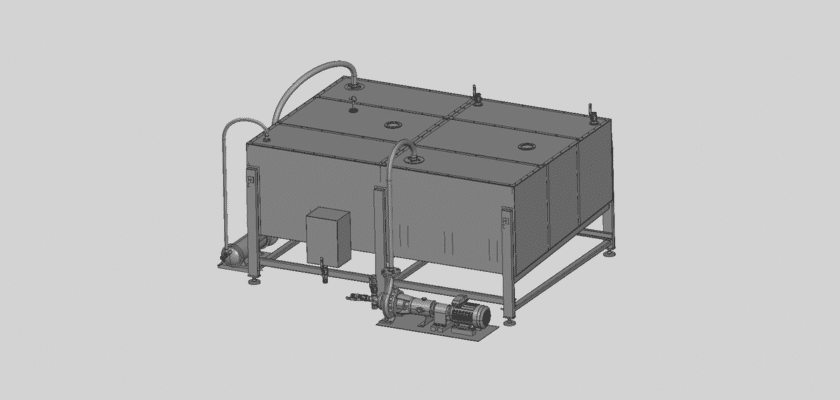

An electrolyte purification station is a critical piece of equipment used in the manufacturing of batteries, particularly lithium-ion batteries. This station is designed to remove impurities from the electrolyte solution, such as water and other contaminants, to ensure the highest performance and safety of the final product. The purity of the electrolyte directly impacts battery efficiency, lifespan, and thermal stability. Our free drawing provides a detailed look at a professional-grade purification station, making it an essential resource for students, engineers, and companies involved in battery production and research.

Our comprehensive package includes detailed schematics of the station’s main components, including the purification columns, filters, pumps, and control systems. The drawings are meticulously prepared to provide all necessary information, from the layout and piping to the instrumentation and safety features. By downloading these high-quality drawings, you can gain a deeper understanding of the complex processes involved in electrolyte purification. The files are available in common formats like DWG, DXF, and PDF, ensuring easy access and compatibility with your preferred design software. Download your free drawing today and elevate your understanding of this vital chemical process.

Ключевые особенности:

- Multi-Stage Filtration: The drawings illustrate a system with multiple purification stages, including molecular sieves and activated carbon filters, designed to effectively remove various impurities.

- Vacuum and Inert Gas Systems: The designs show how the station maintains an inert atmosphere (e.g., argon or nitrogen) and uses vacuum systems to prevent moisture and oxygen contamination, which are highly detrimental to electrolyte purity.

- Temperature Control: The schematics detail the heating and cooling elements necessary for maintaining the ideal temperature during the purification process, which is crucial for achieving high purity levels.

- Safety and Control Systems: The blueprints highlight essential safety features and automated control systems that monitor pressure, temperature, and flow rates to ensure a secure and efficient operation.