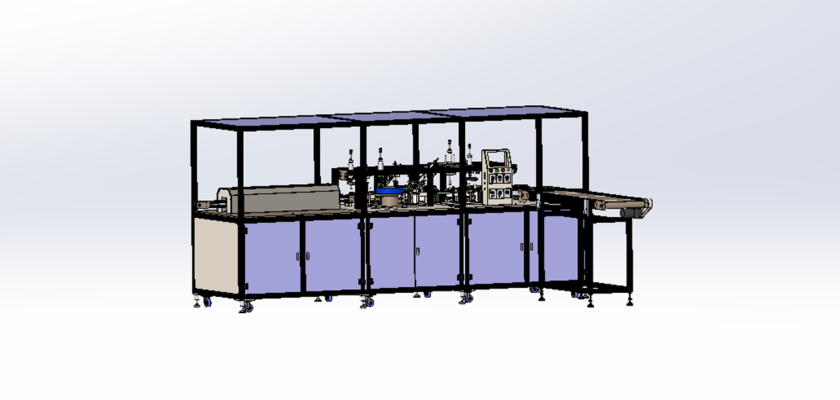

На этом детальном чертеже оборудования для автоматизированной сборки энкодеров представлена специализированная система, предназначенная для точной сборки энкодеров, используемых в различных областях, включая робототехнику, автомобильные системы и промышленную автоматику. Это оборудование идеально подходит для производителей, стремящихся к повышению производительности, обеспечивая высокое качество сборки при сохранении точности процесса.

Основные особенности рисунка:

- Автоматизированный процесс сборки: Оборудование использует передовые технологии автоматизации для упрощения сборки энкодеров, что значительно увеличивает производительность и сокращает потребность в ручном труде.

- Высокоточная обработка компонентов: Система, оснащенная прецизионными приспособлениями и механизмами выравнивания, обеспечивает точное позиционирование и сборку компонентов энкодера, отвечая строгим стандартам качества.

- Удобный интерфейс управления: Интуитивно понятная панель управления позволяет операторам легко программировать и контролировать процесс сборки, обеспечивая быструю настройку для различных моделей и спецификаций энкодеров.

- Универсальная совместимость приложений: разработан для использования с различными типами энкодеров, включая инкрементальные и абсолютные энкодеры, что позволяет адаптировать его для разнообразных применений в различных отраслях.

- Интегрированные функции контроля качества: Оснащены встроенными системами контроля, позволяющими убедиться, что каждый собранный энкодер соответствует стандартам качества, что сводит к минимуму дефекты и повышает общую надежность.

- Прочная и долговечная конструкция: Оборудование изготовлено из высококачественных материалов, спроектировано для долговечности и надежности, гарантируя оптимальную производительность в сложных производственных условиях.

Этот чертеж служит важным справочным материалом для инженеров и производителей, стремящихся внедрить эффективные и производительные решения по сборке энкодеров на своих производственных линиях.