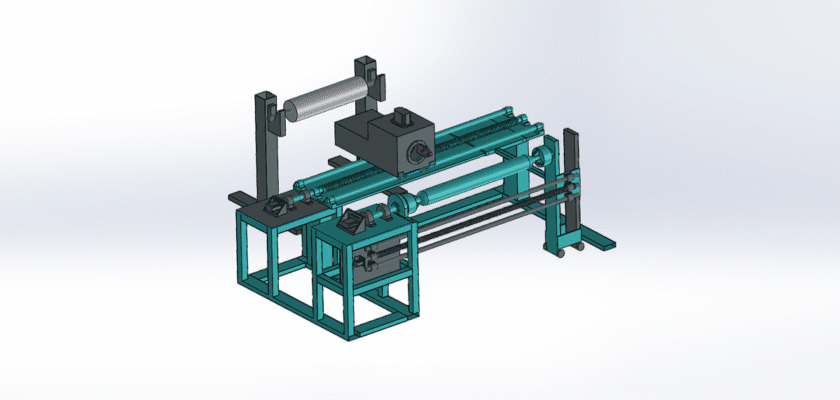

Access the future of lightweight composite manufacturing with our бесплатный загружаемый рисунок из Машина для намотки нити. This detailed engineering blueprint is an invaluable asset for students, professionals, and innovators seeking to understand the technology behind creating high-strength composite structures. The drawing provides an in-depth look at a specialized machine used to produce parts like pressure vessels, pipes, and aerospace components by precisely winding continuous fibers (such as carbon fiber or fiberglass) onto a rotating mandrel. This design meticulously outlines the synchronized motion of the mandrel and the multi-axis fiber delivery system, demonstrating how different winding patterns—like helical, hoop, and polar—are achieved with incredible accuracy. This is a crucial resource for anyone involved in the aerospace, automotive, or industrial sectors, offering insight into a process essential for achieving superior strength-to-weight ratios.

Ключевые особенности:

- Прецизионное управление оправкой: The drawing highlights a robust mandrel with precise angular control, vital for uniform winding.

- Многоосевая доставка волокна: A sophisticated carriage system is detailed, showing how it moves along the mandrel’s length and radius to ensure exact fiber placement.

- Автоматизированная система натяжения: The design includes a tensioning unit that ensures consistent force is applied to the fiber, which is critical for eliminating voids and maximizing part strength.

- Система пропитки смолой: The blueprint provides a clear view of the resin bath, showing how fibers are uniformly saturated with the matrix material before winding.

- Универсальный дизайн: The machine’s modular nature is evident, showcasing its adaptability for producing various shapes and sizes, from simple cylinders to complex pressure domes.