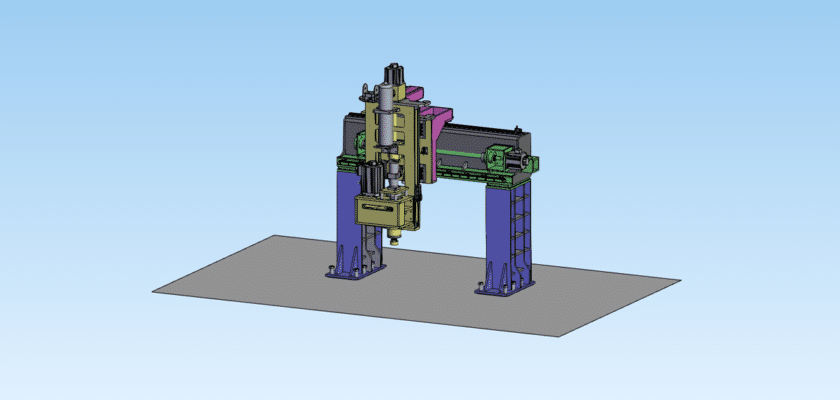

Achieve industrial-scale precision by choosing to download our professional Портальный фрезерный станок drawing. Known for its massive work envelope and exceptional structural rigidity, the gantry milling machine is the cornerstone of heavy-duty manufacturing. This technical drawing provides a detailed blueprint of the machine’s bridge-style architecture, showcasing how the elevated cross-rail and twin-column design provide a stable platform for high-torque spindle operations. It is an essential asset for mechanical engineers and plant managers involved in the production of large-scale molds, aerospace frames, and energy sector components.+1

By utilizing this comprehensive CAD resource, you can analyze the critical mechanical interfaces that allow for high-speed traverses without compromising on accuracy. The drawing covers the intricate arrangement of linear guideways, the drive transmission system, and the robust base casting required to support multi-ton workpieces. Whether you are looking to understand the kinematics of the Z-axis ram or the synchronization of the dual-drive X-axis, these schematics offer the verified data needed for maintenance, retrofitting, or custom machine design. Download this resource to gain a professional perspective on one of the most capable milling platforms in the modern industrial world.

Ключевые особенности:

- High-Rigidity Bridge Structure: Features a reinforced box-type cross-rail designed to counteract torsional forces and minimize deflection during heavy side-milling.

- Synchronized Twin-Drive System: Detailed schematics for the dual-servo drive arrangement that ensures perfectly parallel movement across the longitudinal axes.

- High-Load Floor Bed Design: Specifications for a heavy-duty, fixed-table base that remains thermally stable and vibration-resistant under extreme weight.

- Telescopic Way Covers: Integrated protection layouts for the precision guideways, ensuring long-term durability against heavy chip loads and coolant spray.

- Modular Spindle Head Mount: A versatile interface design that accommodates various spindle power ratings and automatic tool-changing configurations.