Secure your largest industrial components with our professional Heavy Workpiece Clamping Mechanism drawing. When handling workpieces weighing hundreds or thousands of kilograms, standard pneumatic clamps often lack the necessary “bite” to resist the massive cutting forces of a CNC mill or the thermal expansion of a welding process. This technical blueprint provides a high-strength solution utilizing hydraulic or high-ratio mechanical leverage to ensure absolute zero-movement of heavy castings, forgings, or structural plates.

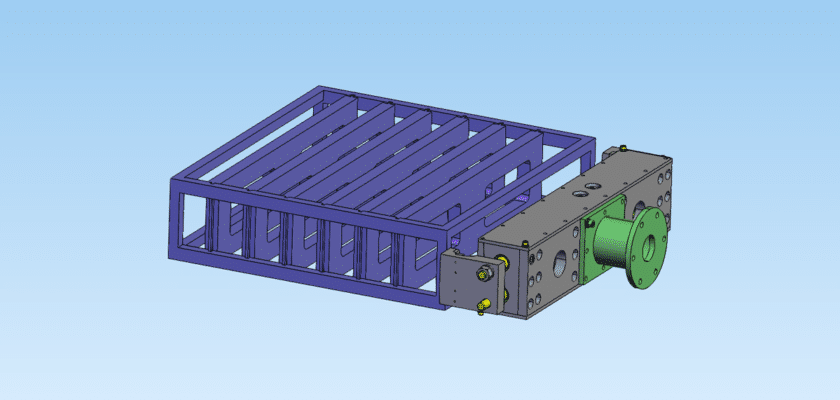

The design focuses on structural rigidity and force multiplication. By downloading this drawing from MechStream, you receive a detailed layout of the reinforced clamping arms, the heavy-duty pivot pins, and the integrated mounting base. The mechanism is engineered to distribute clamping pressure evenly, preventing localized deformation in the workpiece while providing a massive holding force. The schematics include specific details on hydraulic porting for 70MPa systems and manual override points for emergency situations.

Implementing this professional-grade clamping solution is critical for maintaining safety standards in a heavy-manufacturing environment. The documentation highlights the use of alloy steels with specialized heat treatments for the contact jaws and provides safety factor calculations for the pivot points. Whether you are building a fixture for a 5-axis gantry mill or a heavy-duty assembly jig for aerospace components, this drawing provides the structural integrity and mechanical reliability required for high-stakes industrial applications.

Ключевые особенности:

- High-Force Hydraulic Integration: Optimized for high-pressure hydraulic cylinders that deliver massive clamping loads in a compact envelope.

- Positive-Lock Linkage: Features a mechanical toggle-lock design that maintains clamping force even if hydraulic pressure is lost during the cycle.

- Reinforced Structural Frame: Engineered with heavy-section steel components designed to resist deflection under maximum load conditions.

- Self-Leveling Clamping Jaws: Includes spherical washers or pivoting jaw faces that adapt to uneven or cast surfaces for maximum surface contact.

- Hardened Wear Surfaces: Detailed specifications for induction-hardened contact points to prevent scoring and ensure a long service life under abrasive conditions.