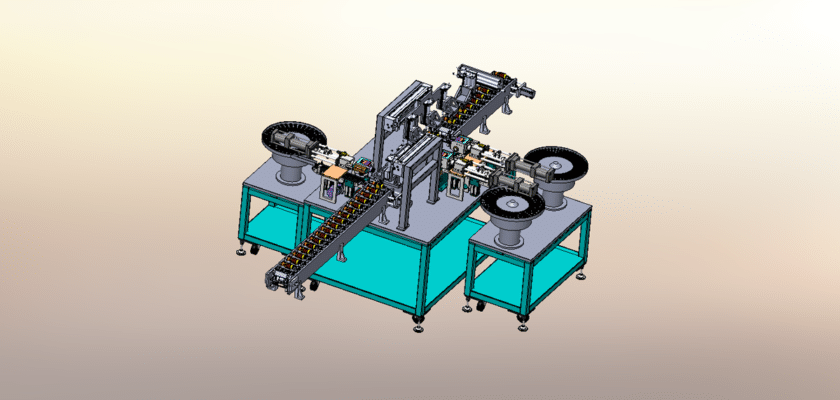

Этот подробный чертеж пресс-сборочного станка для роторов двигателей демонстрирует специализированную систему, предназначенную для точной сборки и прессования роторов двигателей. Этот станок идеально подходит для производителей электродвигателей, повышая эффективность производства, обеспечивая высокое качество сборки и производительность.

Основные особенности рисунка:

- Автоматизированный процесс прессования: В машине используется передовая технология автоматизации для упрощения прессования и сборки компонентов ротора двигателя, что значительно увеличивает производительность и снижает затраты ручного труда.

- Высокопрочный пресс-механизм: Оснащенное надежной системой прессования, оборудование применяет контролируемое усилие для обеспечения оптимальной посадки и выравнивания деталей ротора, способствуя структурной целостности.

- Удобный интерфейс управления: Интуитивно понятная панель управления позволяет операторам легко устанавливать и контролировать параметры прессования, обеспечивая быструю настройку для различных конструкций и спецификаций роторов.

- Прецизионное выравнивание компонентов: Конструкция включает в себя функции, которые обеспечивают точное совмещение компонентов ротора во время сборки, сводя к минимуму риск несоосности и повышая общую производительность.

- Интегрированные системы контроля качества: Встроенные механизмы контроля непрерывно контролируют процесс сборки, гарантируя, что каждый ротор соответствует строгим стандартам качества и сводя к минимуму дефекты.

- Универсальная совместимость приложений: Разработан для использования с роторами различных размеров и конфигураций, что позволяет адаптировать его для различных применений двигателей в различных секторах.

- Прочная и долговечная конструкция: Изготовленная из высококачественных материалов, машина спроектирована для долговечности и надежности, гарантируя оптимальную производительность в условиях высокопроизводительного производства.

Этот чертеж служит важным справочным материалом для инженеров и производителей, стремящихся внедрить эффективные и производительные решения по сборке роторов двигателей в своих производственных операциях.