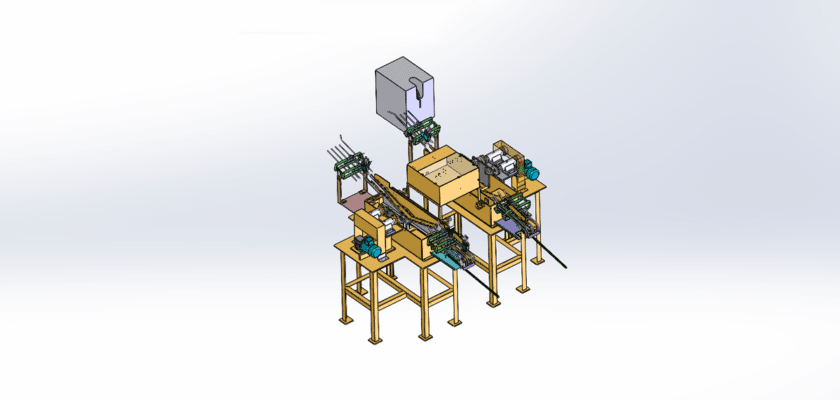

The Non-Standard Automatic Feeder drawing provides a detailed schematic of a customized feeding system designed to automate the delivery of materials or products in industrial and manufacturing settings. This drawing highlights essential components and features that ensure efficient operation, adaptability, and reliability.

Ключевые особенности:

- Feeder Configuration: The drawing illustrates the overall layout of the automatic feeder, showcasing its unique design tailored to specific material types and operational requirements. This includes the arrangement of hoppers, chutes, and conveyor sections.

- Material Handling Mechanism: Detailed information on the feeding mechanism is provided, which may include vibrating trays, belt conveyors, or augers. This section explains how materials are moved from the supply source to the processing or assembly area, ensuring smooth and continuous flow.

- Системы управления: An overview of the control mechanisms is included, detailing how the automatic feeder operates. This may involve programmable logic controllers (PLCs), sensors for material detection, and user-friendly interfaces for adjustments. Safety features such as emergency stop buttons and overload sensors are clearly marked.

- Энергосистема: The drawing highlights the power systems used to operate the feeder, including electric motors and drive mechanisms. Specifications regarding motor power, speed control, and energy efficiency are included to ensure reliable performance.

- Структура поддержки: The robust frame and support system are depicted, emphasizing stability and durability to handle the weight of materials during operation. The design includes anchoring points and structural assessments to ensure safe use.

- Функции безопасности: Essential safety components, such as guards, safety locks, and emergency shutoff mechanisms, are illustrated to promote safe operation and compliance with industry safety standards.

- Доступность обслуживания: Конструкция включает в себя функции, которые обеспечивают легкий доступ к критически важным компонентам для планового обслуживания и осмотров, что способствует эффективному обслуживанию и минимизирует время простоя.

- Варианты настройки: Designated areas for customization are highlighted, allowing for adjustments based on material type, size, and specific operational needs, ensuring flexibility in various applications.

This drawing serves as a vital resource for engineers, production managers, and maintenance personnel, providing comprehensive insights into the design, implementation, and operation of non-standard automatic feeders in diverse industrial applications.