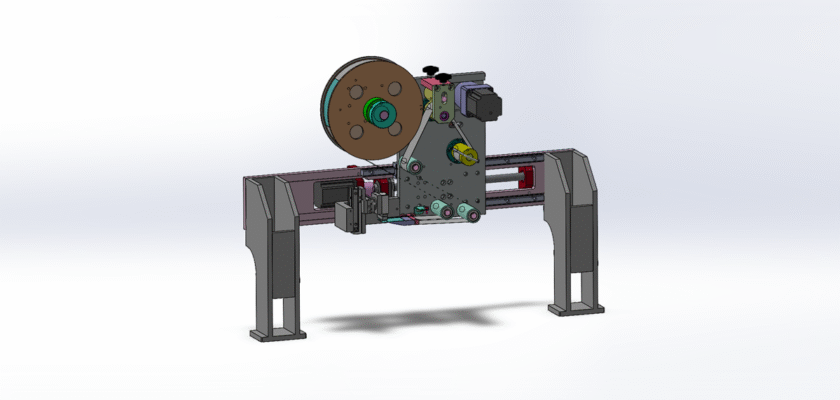

Discover the intricate design of a combined Paper Tearing and Labeling Machine with our exclusive, free-to-download drawing. This innovative blueprint merges the functionality of two essential office and industrial machines into a single, efficient unit. The paper shredding component is engineered to securely destroy documents, rendering sensitive information illegible through a system of inter-meshing rotating blades. These blades, typically made from hardened steel, are mounted on two shafts that rotate in opposite directions, powerfully tearing paper into fine strips or confetti-like pieces. This shredding mechanism is driven by an electric motor, with a gear or belt transmission system providing the necessary torque.

The labeling section of the machine is designed to apply self-adhesive labels to various products or documents. It features a sophisticated system that includes a label dispenser with a peeler plate, a sensor to detect the product, and an applicator that precisely places the label. The conveyor system moves items at a constant speed, ensuring accurate and consistent label placement. This integration streamlines workflows, offering a complete solution for tasks ranging from document preparation and destruction to package labeling. This detailed drawing is an excellent resource for anyone interested in mechanical design, industrial automation, or improving their own production processes.

Ключевые особенности:

- Dual-Functionality: A single machine performs both secure paper shredding and precise product labeling, maximizing space and efficiency in a work environment.

- Robust Tearing Mechanism: The design includes a durable cutting system with interlocked blades and a powerful motor, built to handle high volumes of paper with minimal jamming.

- Automated Labeling System: The machine incorporates sensors and a conveyor to ensure labels are dispensed and applied accurately and consistently, reducing human error.

- Интегрированная система управления: A central control unit, often a PLC (Programmable Logic Controller), coordinates the tearing and labeling processes, allowing for easy operation and customized settings.