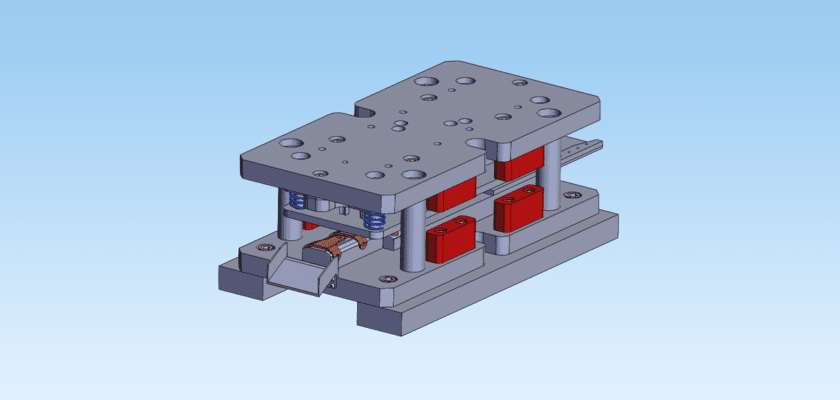

Experience the precision of German-inspired engineering with our Progressive Die “Stanz Und” technical drawing. In the demanding world of high-speed stamping, the “Stanz” (punching) and “Umform” (forming) stages must be perfectly synchronized to ensure part quality and tool longevity. This professional CAD чертеж provides a rigorous blueprint for a multi-stage tool that balances high-tonnage cutting forces with delicate forming requirements. By downloading this resource, you gain access to a proven architecture that follows the highest industrial standards for stability and repeatability.

This download focuses on the technical integration of various press operations within a single progression. The чертеж illustrates advanced concepts such as fine-blanking clearances, precision bending inserts, and high-performance stripping systems. Whether you are developing complex automotive clips or robust industrial housings, this layout offers the structural depth required for reliable 24/7 production cycles. At MechStream, we are dedicated to providing the global engineering community with top-tier, free CAD assets that reflect the best practices in modern tool and die making. Download this “Stanz Und” progression blueprint today and bring a new level of German-standard precision to your manufacturing projects.

Ключевые особенности:

- High-Efficiency Stanz Geometry: Optimized punch designs to minimize burr formation and extend intervals between sharpening.

- Integrated Forming Stations: Specialized “Umform” inserts designed for precise angle control and minimal material springback.

- Modular Plate Construction: Features standardized die sets that allow for the quick exchange of modular inserts for different part variants.

- Robust Tool Steel Specs: Includes technical recommendations for heat-treated tool steels (like 1.2379) to handle high-cycle fatigue.

- Advanced Lubrication Channels: Internal oil distribution paths designed to reduce friction and heat buildup during high-speed stamping.