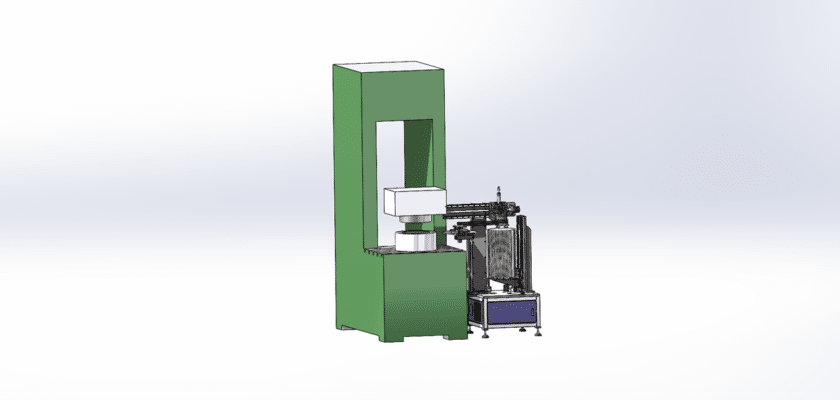

A Punch Robot Feeder Drawing is a detailed technical illustration that depicts the design, components, and functionalities of a robotic feeding system specifically designed for supplying materials to punch machines in manufacturing environments. This drawing is essential for engineers, operators, and technicians involved in the development, operation, and maintenance of such systems.

Ключевые особенности:

- Общая планировка: A comprehensive view of the punch robot feeder system within a production line, showcasing its integration with punch machines and other machinery.

- Механизм подачи: Detailed illustrations of the feeding system, including:

- Belt or Conveyor System: Information about the type of conveyor or feeding mechanism used to transport materials to the punch machine.

- Feed Orientation: Diagrams showing how materials are oriented and positioned for accurate feeding into the punch.

- Структура роботизированной руки: Descriptions of the robotic arm used for handling materials, including:

- Звенья и соединения: Information about the segments (links) and types of joints (revolute, prismatic) that allow for flexible movement.

- Степени свободы: Specifications indicating the range of motion that enables the robot to place or retrieve materials effectively.

- Конструкция конечного эффектора: Details about the tool or gripper attached to the robotic arm, including:

- Механизм захвата: Information on the design and functionality of the gripper used for securely holding and positioning materials.

- Сменные концевые эффекторы: Information on the ability to switch between different tools based on the type of materials being handled.

- Система управления: Подробная информация о блоке управления, который управляет работой робота, включая:

- Контроллер робота: Information on the controller used for programming and executing feeding tasks.

- Пользовательский интерфейс: Illustrations of control panels or software interfaces that allow operators to program feeding parameters and monitor performance.

- Датчики и системы обратной связи: Diagrams showing integrated sensors that provide feedback on the feeding process, such as:

- Датчики положения: Used for ensuring accurate placement of materials into the punch machine.

- Датчики приближения: To detect the presence of materials on the conveyor or in the feeder.

- Функции безопасности: Информация о механизмах безопасности, таких как:

- Emergency Stop Buttons: Details on emergency stop systems to ensure safe operation.

- Safety Guards: Descriptions of protective barriers to prevent accidents during operation.

- Источник питания: Информация об источнике питания, включая:

- Электрические характеристики: Details on the type and capacity of the power supply used for the robotic system and feeding mechanism.

- Мобильность и позиционирование: Информация о базе робота и любых функциях мобильности, включая:

- Fixed or Mobile Base Design: Diagrams showing the stability of the system during operation and any options for repositioning within the production area.

- Точки доступа для обслуживания: Guidance on areas designed for easy access during maintenance and repair, facilitating efficient servicing of the robot and feeding system.

- Технические характеристики: Summary of key performance metrics, such as feeding speed, precision, and material compatibility, providing essential information for operational planning.

- Контекст приложения: Brief descriptions of typical applications for the punch robot feeder in industries such as metalworking, fabrication, and assembly.

This drawing serves as a vital reference for anyone involved in the operation and maintenance of robotic feeding systems for punch machines, ensuring effective performance, reliability, and adherence to industry standards in automated manufacturing.