Maximize your precision assembly with a crucial Robotic Ultrasonic Welding Equipment drawing package, now available for бесплатная загрузка on MechStream. Ultrasonic welding is a high-speed, clean joining technology, particularly favored in the automotive, medical, and consumer electronics industries for bonding plastics and non-ferrous metals. Integrating this technology with robotics creates highly accurate and repeatable automated processes. This collection of technical чертеж САПР files provides the necessary details for seamlessly incorporating ultrasonic welding heads, boosters, and generators into a robotic cell environment.

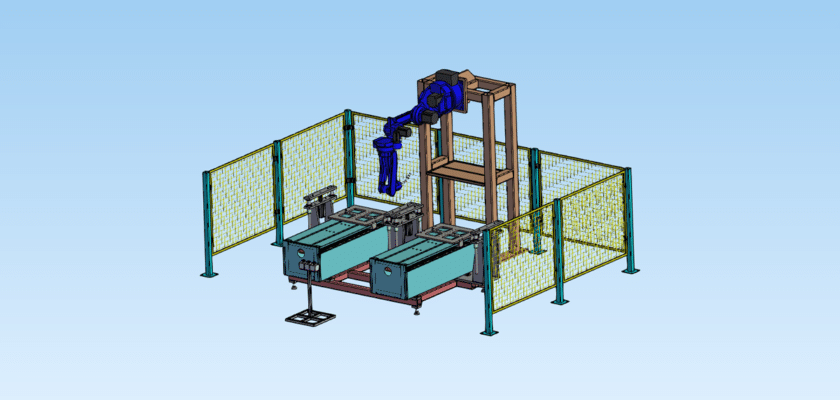

This free чертеж resource is vital for engineers designing automated assembly lines. It includes precise dimensions for mounting the ultrasonic transducer systems onto various robotic arm models, ensuring optimal tool center point (TCP) calibration. The drawings detail the spatial requirements for the generator cabinets and the critical layout of pneumatic and electrical connections, which is essential for stable, high-frequency operation. By utilizing these accurate Robotic Ultrasonic Welding Equipment drawing resources, you can minimize potential design conflicts, accelerate the fabrication of custom jigs and fixtures, and guarantee that the robot’s movement path accounts for all system components. Download these powerful technical assets today to master the precise application of automated ultrasonic welding solutions in your next manufacturing project.

Ключевые особенности:

- Transducer Mounting Details: Provides dimensional and interface specifics for mounting the ultrasonic tooling to the robot end effector.

- Generator Integration: Includes layout and clearance requirements for placing the ultrasonic power generators and control units.

- Acoustic Tooling Schematics: Aids in designing custom horns (sonotrodes) and fixtures (anvils) for specific part geometries.

- Cable Management: Details optimal routing for high-frequency cables and pneumatic lines to maintain signal integrity and safety.

- Cell Footprint: Helps in calculating the required safety enclosure size based on robot reach and peripheral equipment placement.