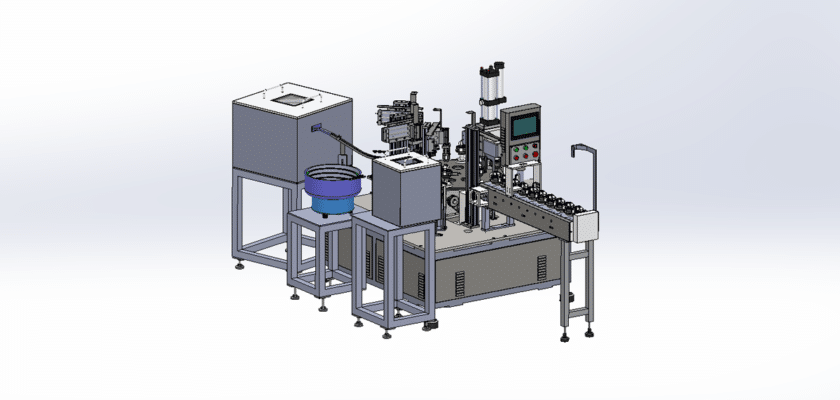

The Screw Nut Automatic Assembly Machine is engineered to automate the process of assembling screws and nuts with high precision and efficiency. Designed for a wide range of applications, this machine streamlines the assembly process, ensuring consistent torque and secure fastening in various industrial components. Its robust design and automated features minimize errors and increase production rates, making it an ideal solution for mass production environments.

Ключевые особенности:

- Automated Assembly Process: Reduces manual labor by automating the screw and nut assembly process, improving efficiency and consistency.

- Precise Torque Control: Equipped with advanced torque control technology to ensure that screws and nuts are tightened to the exact specifications, preventing over-tightening or under-tightening.

- High-Speed Operation: Capable of high-speed assembly, increasing throughput and reducing cycle times.

- Flexible Compatibility: Supports various sizes of screws and nuts, making it suitable for diverse applications in automotive, electronics, and machinery manufacturing.

- User-Friendly Interface: Simple controls and easy adjustments allow for quick setup and minimal downtime.

Applications:

- Widely used in the assembly of automotive parts, electrical appliances, and machinery, where precise screw and nut fastening is critical.

The Screw Nut Automatic Assembly Machine is a reliable and cost-effective solution for industries looking to optimize their assembly lines and improve the quality and consistency of their fastener assemblies.