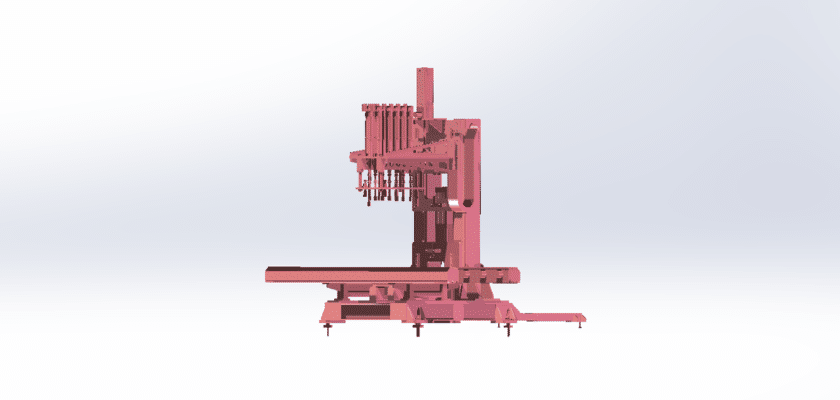

Станция затяжки винтов — это современная полуавтоматическая рабочая станция, предназначенная для точной затяжки винтов на промышленных сборочных линиях. Эта станция, ориентированная на точность и эффективность, обеспечивает контролируемое затягивание винтов с точным соблюдением требуемого момента затяжки, гарантируя стабильные и высококачественные результаты в каждом цикле. Станция затяжки винтов идеально подходит для сборочных операций со средними и высокими объемами производства и представляет собой оптимизированное решение для сокращения ручного труда, повышения производительности и надежности продукции.

Ключевые особенности:

- Точный контроль крутящего момента: Станция затяжки винтов, оснащенная цифровым динамометрическим ключом или усовершенствованным инструментом для затяжки, гарантирует, что каждый винт затянут с точным заданным моментом затяжки, сводя к минимуму риск чрезмерной или недостаточной затяжки.

- Удобный интерфейс: Станция оснащена интуитивно понятной панелью управления, которая позволяет операторам легко задавать значения крутящего момента, отслеживать ход затяжки и корректировать настройки по мере необходимости. Интерфейс упрощает настройку и эксплуатацию, делая её подходящей для быстрой смены задач и различных производственных циклов.

- Эффективная система подачи шнека: Станция оснащена автоматическим или полуавтоматическим механизмом подачи винтов, который подает винты непосредственно к затягивающему инструменту, что сокращает объем ручной работы и ускоряет процесс сборки.

- Мониторинг в реальном времени и обратная связь: Встроенные датчики обеспечивают мониторинг каждой операции затяжки в режиме реального времени, гарантируя правильность крепления винтов и предупреждая оператора в случае возникновения ошибок (например, если винт отсутствует или не затянут должным образом).

- Гибкая и регулируемая конструкция: Станцию можно легко адаптировать под различные размеры, типы и области применения винтов, что обеспечивает универсальность для широкого спектра продукции: от небольших электронных устройств до крупных автомобильных компонентов.

- Компактный и модульный: Компактная и модульная конструкция позволяет легко интегрировать станцию затяжки в существующие производственные линии, что делает ее идеальным вариантом как для новых установок, так и для модернизации существующих рабочих процессов.

- Долговечность и надежность: Станция затяжки винтов, изготовленная из высококачественных промышленных компонентов, рассчитана на длительную надежность и может выдерживать нагрузки, связанные с непрерывной работой в условиях высокопроизводительного производства.

Приложения:

- Подходит для таких отраслей промышленности, как автомобилестроение, электроника, производство потребительских товаров и промышленного оборудования, где стабильное и надежное крепление винтов имеет решающее значение для качества и безопасности продукции.

- Идеально подходит для применений, связанных со сборкой электронных компонентов, машин, корпусов и других механических или конструктивных деталей, требующих точной затяжки винтов.

Станция затяжки винтов — это эффективное и надежное решение для автоматизированного или полуавтоматического затягивания винтов, обеспечивающее прочное и стабильное соединение в каждом цикле. Благодаря усовершенствованному контролю крутящего момента и автоматической подаче винтов, она повышает качество сборки, снижает количество ошибок и повышает производительность на линиях среднего и большого объёма производства.