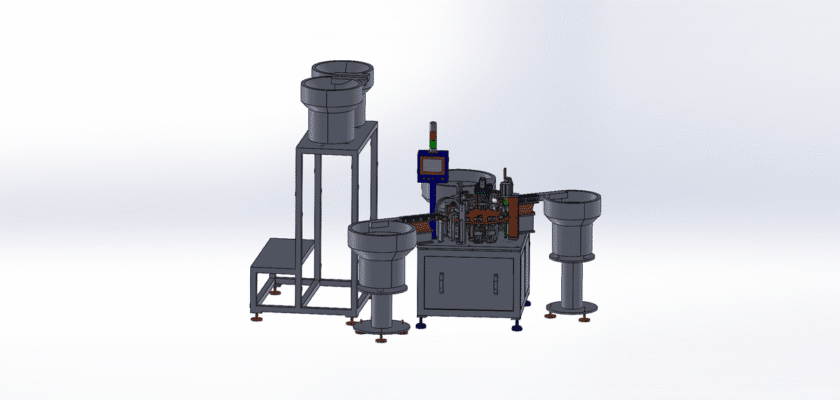

Откройте для себя мир автоматизированной упаковки с помощью нашего бесплатного чертежа сборки крышки для шампуня. Этот подробный чертеж подробно описывает оборудование, отвечающее за один из важнейших этапов в индустрии средств личной гигиены: надёжную и точную укупорку флаконов шампуня. Для инженеров, студентов и производителей этот чертеж — бесценный источник информации для понимания механизма и конструкции высокоскоростной сборочной линии. Сложный процесс сортировки, позиционирования и укупорки бутылок детально прорисован, что позволяет лучше понять эффективность и контроль качества.

На чертеже выделены ключевые компоненты и их синхронизация, демонстрируя, как машина для сборки колпачков обеспечивает защиту от вскрытия и предотвращает утечки, что крайне важно для целостности продукта и доверия потребителей. Этот чертеж — от вибропитателей, выравнивающих колпачки, до высокоскоростных укупорочных головок, обеспечивающих постоянный крутящий момент, — идеальное обучающее пособие. Скачайте его бесплатно и начните свой следующий проект, будь то проектирование новой машины или просто изучение технологий, которые обеспечивают безопасность и готовность наших любимых продуктов к использованию.

Ключевые особенности:

- Автоматизированный процесс укупорки: На чертеже показан весь автоматизированный процесс — от первоначальной подачи крышек до окончательного закручивания крышки на бутылке, что позволяет увидеть весь процесс целиком.

- Детализация на уровне компонентов: Изучите конструкцию критически важных компонентов, таких как вибрационная чаша питателя для ориентации крышки, робот-погрузчик для точного размещения и укупорочный патрон который прикладывает контролируемый крутящий момент к каждой крышке.

- Универсальный дизайн: На схеме представлена модульная конструкция, которую можно адаптировать под различные типы крышек, включая откидные, винтовые и дозаторы с помпой, что демонстрирует гибкость машины.

- Эффективность и скорость: Узнайте, как машина достигает высокой производительности за счет синхронизированных движений и оптимизированной сборки, что является отличительной чертой современного производства.

- Интеграция обеспечения качества: На чертеже показаны функции контроля качества, такие как расположение датчиков для обнаружения неправильно установленных или отсутствующих крышек, что гарантирует идеальную герметизацию каждой бутылки перед тем, как она покинет производственную линию.