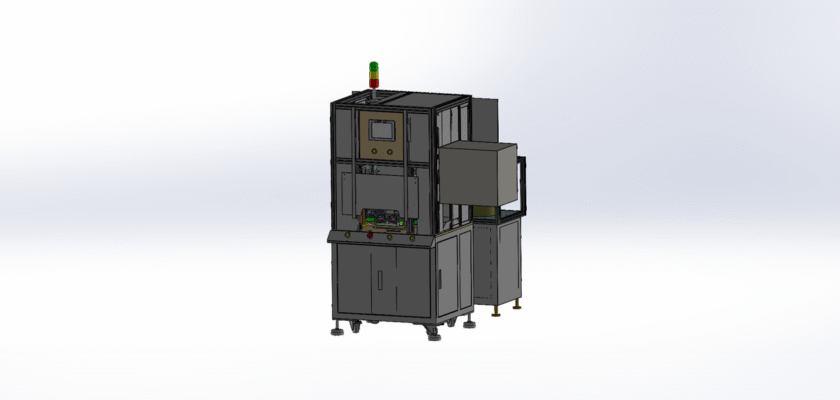

Измените процесс сборки с помощью наших комплексных решений Шестикоординатный винтовой зажимной станок Рисунок. Этот мощный чертеж Это важный ресурс для инженеров и производителей, стремящихся к безупречной, высокоскоростной сборке с непревзойденной точностью. Схема представляет собой современную роботизированную систему, предназначенную для автоматизации зачастую трудоемкой и подверженной ошибкам операции завинчивания. Используя шестиосный роботэта машина может получить доступ к винтам под любым углом и в сложных, труднодоступных местах, что невозможно для традиционных, менее универсальных машин.

Это не просто план, это руководство по передовой автоматизации. чертеж Подробно рассматриваются ключевые компоненты, включая роботизированный манипулятор, систему автоматической подачи винтов и механизм точного контроля крутящего момента. В нём подробно объясняется, как эта система обеспечивает затяжку каждого винта с правильным моментом, предотвращая повреждение изделия и гарантируя стабильно высокое качество сборки. Для всех, кто работает в сфере электроники, автомобилестроения или производства потребительских товаров, это руководство чертеж — это важнейший инструмент для проектирования производственной линии, которая обеспечивает максимальную эффективность, снижает человеческий фактор и повышает общую надежность продукции. Загрузите этот важный инструмент. чертеж сегодня и продвиньте свои производственные возможности в будущее.

Ключевые особенности:

- Усовершенствованная роботизированная точность: На рисунке показан полный диапазон движения шестиосный робот, демонстрируя его способность достигать и закручивать винты в сложных трехмерных пространствах с исключительной точностью.

- Автоматизированная шнековая подача: В нем подробно описана интегрированная система подачи винтов, которая автоматически подает винты к рабочему органу робота, что значительно сокращает время цикла и повышает скорость производства.

- Постоянный контроль крутящего момента: На схеме показаны важнейшие системы измерения крутящего момента и обратной связи, которые гарантируют, что каждый винт будет затянут в точном соответствии со спецификациями, исключая недотягивание или перетягивание.

- Универсальное применение: Этот чертеж — это гибкая конструкция, которую можно адаптировать для широкого спектра продукции: от смартфонов и ноутбуков до автомобильных компонентов, что делает ее универсальным решением для автоматизированной сборки.

- Повышенная надежность продукта: Обеспечивая надежную фиксацию каждого винта, система, подробно представленная на этом чертеже, напрямую способствует долговечности и долгосрочной надежности конечного продукта.