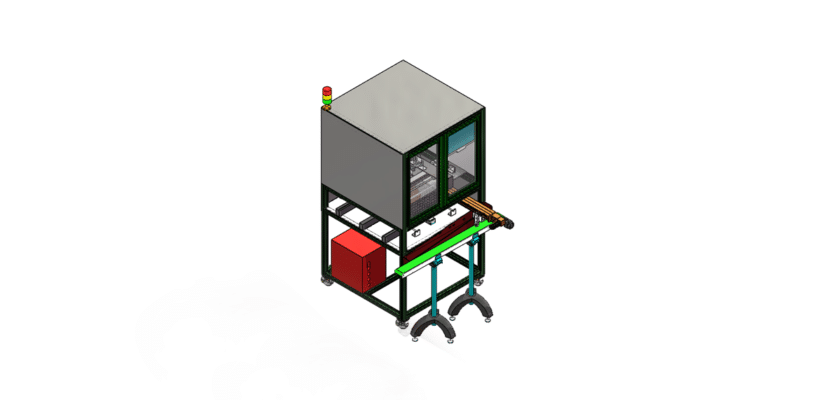

Чертёж машины для контроля мелких деталей — это техническая иллюстрация, демонстрирующая компоненты и компоновку машины, предназначенной для контроля и обнаружения мелких деталей в процессе производства. Машины такого типа необходимы для обеспечения контроля качества и точности производственных процессов.

Ключевые особенности:

- Зона инспекции: Схемы, показывающие выделенное пространство, где располагаются мелкие детали для обнаружения, с указанием приспособлений или лотков, которые надежно удерживают предметы во время проверки.

- Датчики обнаружения: Изображение датчиков, используемых для определения и измерения различных характеристик деталей, таких как размер, форма и дефекты поверхности. К ним могут относиться оптические датчики, лазерные сканеры или тактильные датчики.

- Конвейерная система: Подробная информация об автоматизированном конвейере или транспортном механизме, который перемещает заготовки через зону контроля, обеспечивая эффективную обработку и сводя к минимуму ручное вмешательство.

- Блок управления: Информация об устройстве обработки, которое управляет операциями обнаружения, анализирует данные с датчиков и определяет качество заготовок.

- Пользовательский интерфейс: Иллюстрации панели управления или сенсорного экрана, которые позволяют операторам контролировать процесс обнаружения, задавать параметры и просматривать результаты в реальном времени.

- Системы вывода данных: Схемы, показывающие, как передаются результаты обнаружения, включая цифровые дисплеи для немедленной обратной связи, регистрацию данных для контроля качества и подключение к внешним системам отчетности.

- Механическая конструкция: Информация о конструктивных элементах, на которых базируется детекторная машина, обеспечивающая ее устойчивость и точность во время работы.

- Источник питания: Подробная информация о требованиях к электропитанию, включая электрические соединения и любые резервные системы для обеспечения надежной работы.

Данный чертеж служит всеобъемлющим справочным материалом для инженеров и техников, занимающихся проектированием, сборкой и обслуживанием машин для обнаружения мелких деталей, обеспечивая высокие стандарты контроля качества и эксплуатационную эффективность производственных процессов.