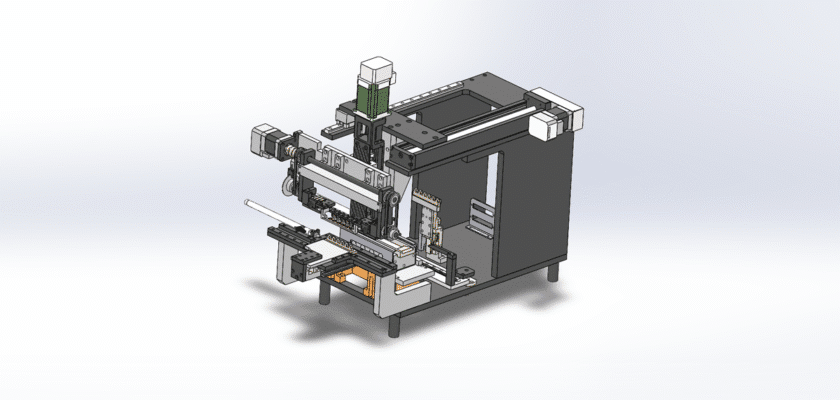

Шагните в мир высокотехнологичного производства электроники с нашим бесплатным Машина для сварки катушек SMD Чертеж. Этот подробный комплект чертежей представляет собой полное описание сложной системы, предназначенной для автоматизации критически важного процесса сварки тонкой проволокой с компонентами поверхностного монтажа (SMD). Этот ресурс идеально подходит для инженеров, исследователей и студентов и предлагает ценную информацию о механических и электрических конструкциях, лежащих в основе технологии прецизионной микросварки.

Концепция машины представляет собой полностью автоматизированное решение, объединяющее намотку, сварку и контроль качества в единый, бесперебойный процесс. Автоматизация этих задач исключает ошибки ручного труда, значительно увеличивает скорость производства и обеспечивает стабильное качество чувствительных электронных компонентов, таких как катушки индуктивности и дроссели. Загрузка этих профессиональных чертежей даёт вам уникальную возможность изучить инженерные принципы, лежащие в основе современной крупносерийной сборки электроники. Получите конкурентное преимущество, поняв, как проектировать и внедрять системы, обеспечивающие точность и эффективность в микромасштабе.

Ключевые особенности:

- Высокоточная сварка: Конструкция включает в себя усовершенствованную сварочную головку с точной системой управления движением, гарантирующую постоянную прочность и точность микросварных швов, что имеет важное значение для надежности мелкосерийных электронных компонентов.

- Автоматизированная обработка проводов: Машина автоматизирует деликатный процесс подачи, намотки и резки тонкой проволоки, сводя к минимуму отходы материала и обеспечивая высокую степень повторяемости и скорости.

- Комплексный контроль качества: На чертеже показана система со встроенной технологией технического зрения и датчиков, которая автоматически проверяет каждый сварной компонент, выявляя и отбраковывая дефекты в режиме реального времени для поддержания высокого уровня выхода годных изделий.

- Программируемая операция: Конструкция включает в себя систему управления, которая позволяет легко программировать параметры сварки, обеспечивая быструю смену различных спецификаций SMD-катушек и гарантируя универсальность для различных производственных нужд.

- Компактный и эффективный: Машина, спроектированная с учетом небольших габаритов, позволяет максимально эффективно использовать производственное пространство, обеспечивая при этом высокую скорость работы, что делает ее эффективным решением для крупномасштабных производственных линий.