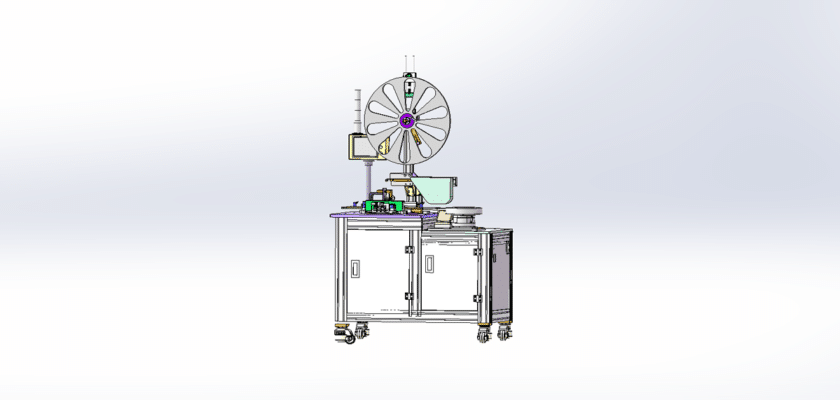

На этом чертеже показана конструкция и компоновка нестандартного автоматического сборочного станка для поверхностного монтажа (SMD), предназначенного для высокоточной сборки электронных компонентов. Станок разработан для установки различных нестандартных SMD-компонентов, что обеспечивает гибкость производства.

Ключевые особенности:

- Модульная конструкция: Модульная архитектура машины обеспечивает легкую настройку и масштабируемость, позволяя адаптировать ее к различным требованиям сборки.

- Автоматизированная система кормления: Благодаря интегрированному усовершенствованному механизму подачи машина эффективно подает компоненты в зону сборки, сводя к минимуму время простоя.

- Точное размещение: Станок оснащен высокоточными установочными головками, что обеспечивает точное выравнивание и позиционирование SMD-компонентов на печатных платах (ПП).

- Система управления: Интуитивно понятный интерфейс управления оснащен программируемыми настройками, позволяющими операторам легко настраивать параметры для различных задач сборки.

- Контроль качества: Встроенные системы технического зрения облегчают проверку в режиме реального времени, гарантируя правильность установки и пайки каждого компонента.

- Компактный размер: Разработан для эффективного использования пространства, что делает его пригодным как для небольших, так и для крупных производственных сред.

Этот чертеж служит всеобъемлющим руководством для инженеров и техников, участвующих в процессе сборки, в нем указаны критические размеры, расположение компонентов и рабочие процессы.