In precision motion control, maintaining the perfect amount of preload is essential to prevent tooth jumping and premature wear. This Tension Device For Synchronous Conveyor Belt CAD чертеж provides a high-performance engineering solution for maintaining constant tension in timing belt systems. Unlike standard friction belts, synchronous belts require exact positioning to ensure that the belt teeth mesh perfectly with the pulleys. This device is designed to eliminate slack and absorb small vibrations, ensuring that your conveyor system operates with maximum positional accuracy and minimal noise.

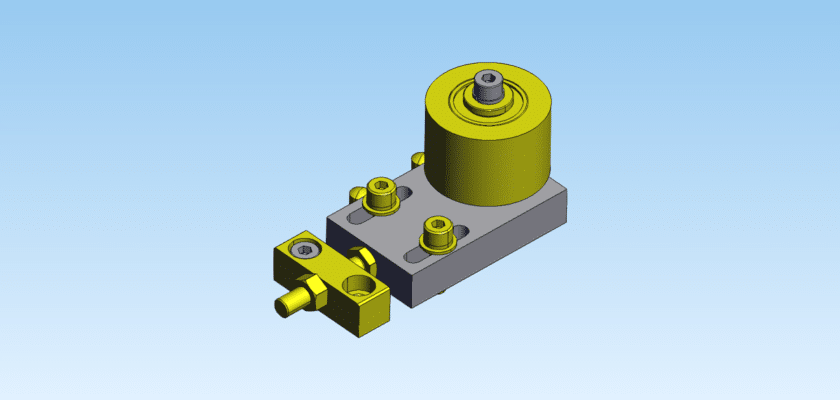

By downloading this professional чертеж, you receive a blueprint for a robust, adjustable tensioning assembly. The design features a linear or rotary take-up mechanism that allows for fine-tuned adjustments during installation and maintenance. By incorporating this tensioner into your machine design, you significantly extend the service life of the belt and the motor bearings by preventing over-tensioning. The assembly is optimized for industrial environments, using materials that resist deformation under load. Whether you are designing a 3D printer gantry, an automated packaging line, or a high-speed sorting conveyor, this technical resource provides the precise tolerances and mounting configurations needed for a reliable build.

Ключевые особенности:

- Fine-Thread Adjustment: Features a high-precision lead screw for granular control over belt tension, allowing for micro-adjustments without disassembling the drive.

- Spring-Loaded Compensation: Includes an optional internal spring mechanism to maintain consistent tension even as the belt naturally stretches over time.

- Low-Friction Idler Pulley: Specifications for a high-speed rated idler with integrated sealed bearings to reduce drag and heat buildup.

- Universal Mounting Slots: The base plate includes elongated slots, making it compatible with a wide range of aluminum extrusion profiles and flat machine frames.

- Rigid Anti-Flex Construction: The structural arm is engineered to resist bending under high torque, ensuring the idler pulley remains perfectly parallel to the drive pulleys.