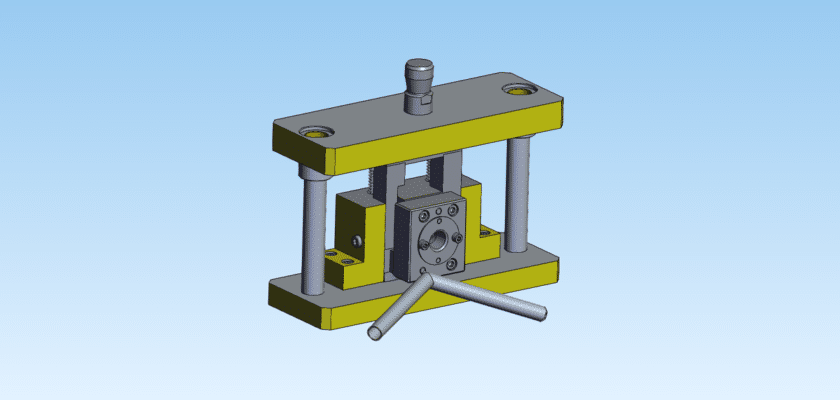

Achieve seamless joinery in your tubular structures with our Tubing Notcher Die CAD drawing. In high-performance fabrication, such as roll cage construction or bicycle frame building, the “fish-mouth” or cope cut must be perfect to ensure strong, clean weld beads. This technical чертеж provides a detailed blueprint for a press-actuated notcher die designed to shear circular profiles into the ends of tubing with surgical accuracy. By utilizing a die-based shearing method rather than hole saws, you can significantly increase production speed while eliminating the mess of metal chips and coolant.

This download provides a deep dive into the specialized geometry required to prevent tube collapsing during the shearing process. The layout features a contoured punch and a matching radius die bed that supports the tube wall throughout the entire stroke. By studying this чертеж, you can analyze the internal clearances needed for different wall thicknesses and the integrated stop-blocks for repeatable notch depths. Whether you are working with Chromoly, stainless steel, or aluminum, this resource provides the engineering foundation for a robust, industrial-grade coping solution. At MechStream, we prioritize assets that help you achieve “tight-fit” geometry for superior structural integrity.

Ключевые особенности:

- Contoured Shearing Interface: Specifically designed punch and die radii that match standard tubing ODs for a burr-free finish.

- Anti-Collapse Support: Features a rigid internal or external support structure to maintain tube roundness during high-pressure shearing.

- Adjustable Angle Notching: Detailed views of the pivoting base or angled shims used to create cope cuts for non-90-degree joints.

- Hardened Shock-Resisting Steel: Specifications for S7 or similar tool steels designed to withstand the high-impact loads of tubing shear.

- Slug Ejection Chute: Integrated gravity-fed path for cut-offs to clear the tool instantly, preventing jams in high-volume production.