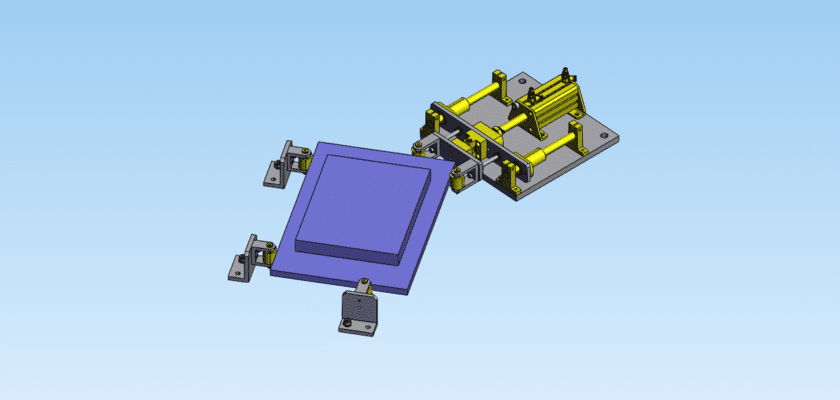

Accuracy is the foundation of quality in modern manufacturing, and achieving it consistently requires a reliable way to locate parts. This Workpiece Positioning Mechanism CAD чертеж provides an expert-level blueprint for a system designed to fix and align workpieces in a repeatable “home” position. In automated production, sensors and cutting tools rely on the part being in an exact coordinate every time. This mechanism utilizes mechanical stops and precision centering logic to eliminate positional drift, ensuring that your robotic grippers, drill bits, or inspection cameras interact with the component at the perfect 3D coordinates.

By downloading this professional чертеж, you gain access to a versatile design that can be integrated into conveyor lines, CNC fixtures, or manual assembly benches. The assembly focuses on high-rigidity and low-clearance motion, utilizing hardened reference surfaces that resist wear over thousands of cycles. Whether you are dealing with irregular castings or flat sheet metal, this positioning solution provides the mechanical stability needed to reduce scrap rates and improve cycle times. The documentation includes comprehensive details on the linkage systems and mounting tolerances required to build a world-class industrial positioning unit.

Ключевые особенности:

- Self-Centering Logic: Features a synchronized linkage or V-block design that automatically centers workpieces of varying sizes along a common centerline.

- Hardened Datum Points: Specifications include heat-treated steel pins and blocks to maintain sub-millimeter accuracy even under continuous industrial use.

- Adjustable Stroke Limiters: Includes fine-thread adjustment bolts that allow the operator to calibrate the final stopping position with extreme precision.

- Multi-Axis Constraint: The structural design ensures the workpiece is constrained in all six degrees of freedom, preventing any shifting during high-force operations.

- Pneumatic Port Integration: Designed for easy connection to standard pneumatic cylinders for high-speed, automated clamping and positioning cycles.