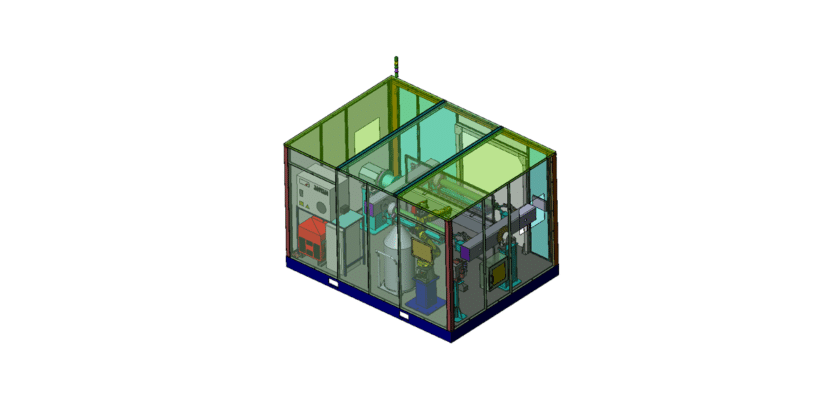

The Shock Absorber Robot Welding Workstation Drawing outlines an advanced solution for precise and automated welding processes in shock absorber manufacturing. This workstation is specifically engineered to meet the demands of high-precision welding, ensuring strong and durable connections in automotive and industrial applications.

One of the key features of this workstation is its robotic precision welding technology, which guarantees consistent weld quality and reduces the risk of errors. The robotic arm operates with high repeatability, maintaining accuracy across complex welding tasks.

Another standout feature is its integrated automation system, allowing seamless coordination between robot motion, welding parameters, and production lines. This automation minimizes manual intervention, enhancing efficiency and productivity.

The workstation also includes advanced control software, enabling operators to set precise welding parameters and monitor operations in real-time. This ensures optimal performance and allows for quick adjustments when needed.

Furthermore, the modular design of the workstation makes it adaptable to various production scales. It can be easily customized to accommodate different shock absorber models and welding requirements.

Durability is also a highlight, with high-strength components ensuring reliable, long-term operation even under continuous heavy workloads.

In conclusion, the Shock Absorber Robot Welding Workstation is a reliable, high-performance solution for manufacturers seeking precision, efficiency, and adaptability in shock absorber production. It is an essential addition to any modern industrial welding facility.

4o