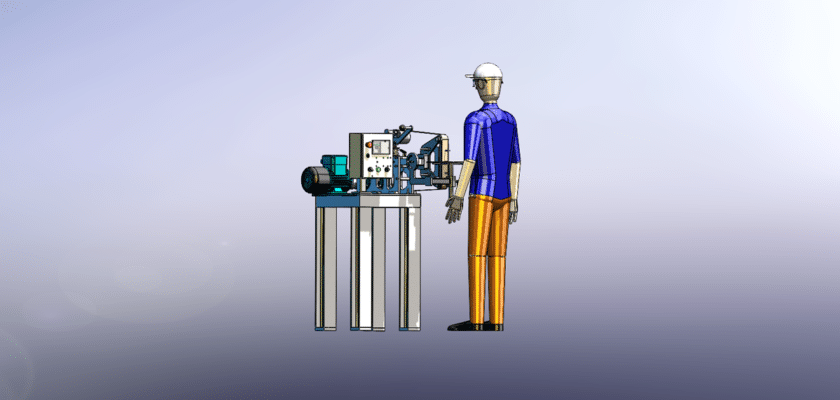

The Sleeve Machine is designed for the efficient manufacturing and assembly of sleeves used in various applications. This drawing illustrates the machine’s key components and functionality, highlighting its ability to streamline production processes.

Key Features:

- Multi-Station Design: The machine incorporates multiple stations to facilitate simultaneous operations, enhancing productivity and reducing cycle time.

- Precision Engineering: Components are designed for accurate alignment and positioning, ensuring high-quality assembly of sleeves.

- User-Friendly Interface: An intuitive control panel allows for easy operation and monitoring of the machine’s performance.

- Robust Construction: Built with durable materials, the machine is capable of withstanding rigorous industrial use.

- Automatic Feeding System: An automated feeding mechanism ensures a continuous supply of materials, minimizing manual intervention.

- Adaptable Settings: The machine can be adjusted for different sleeve sizes and specifications, providing versatility in production.

This drawing serves as a comprehensive guide for understanding the assembly process and mechanical layout of the Sleeve Machine, showcasing its role in modern manufacturing environments.