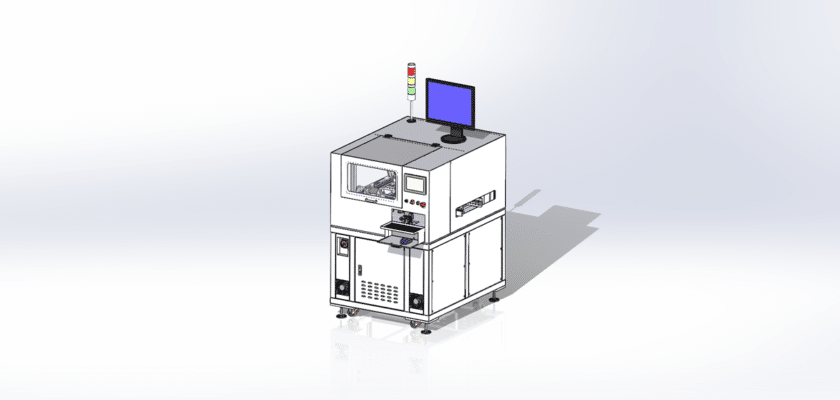

A SMT (Surface Mount Technology) Online Visual Barcode Machine Drawing is a technical illustration that outlines the components and layout of a machine designed for real-time visual inspection and barcode scanning in SMT assembly lines. This type of machine is essential for ensuring quality control and traceability of components during the manufacturing process.

Key Features:

- Inspection Area: Diagrams showing the designated space where circuit boards or components pass through for visual inspection, featuring fixtures that securely hold the items during the scanning process.

- Camera System: Representation of high-resolution cameras positioned to capture images of the components and barcodes, ensuring optimal coverage for accurate scanning and inspection.

- Barcode Scanner: Details about the integrated barcode scanning system that reads and verifies barcodes on components, ensuring proper identification and traceability.

- Lighting Setup: Information on the illumination system, such as LED lights, designed to provide consistent lighting conditions for both visual inspection and barcode scanning.

- Control Unit: Information on the processing unit that manages the inspection and scanning operations, analyzes the captured images, and verifies barcode data against the production database.

- User Interface: Illustrations of the control panel or touchscreen that allow operators to monitor the inspection and scanning processes, adjust settings, and view real-time results.

- Data Output Systems: Diagrams showing how inspection and scanning results are communicated, including digital displays for immediate feedback, data logging for tracking quality metrics, and connections to external systems for reporting.

- Mechanical Framework: Information about the structural components that support the machine, ensuring stability and precision during operation.

- Power Supply: Details regarding the power requirements, including electrical connections and any backup systems to ensure reliable operation.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of SMT online visual barcode machines, ensuring high standards of quality control and operational efficiency in electronic manufacturing processes.