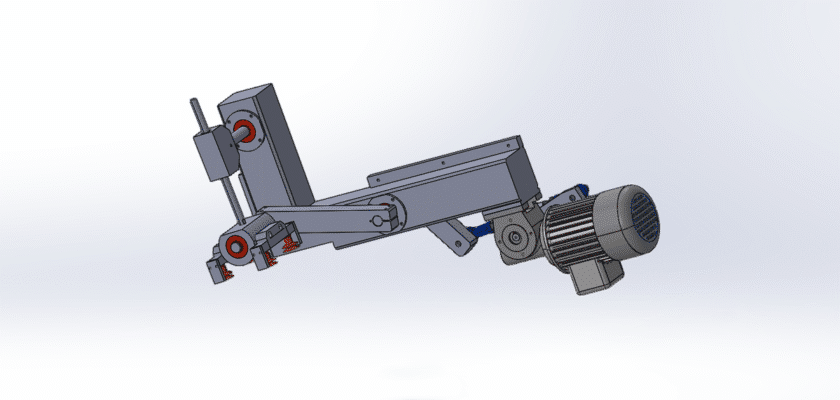

Master the fundamentals of factory automation with our detailed drawing of a Super Classic 90-Degree Pick-And-Place Mechanism. This free, downloadable resource is a must-have for students, engineers, and designers who want to understand the core principles of high-speed, repeatable component handling. This mechanism is a foundational element in a wide array of industrial applications, including electronics manufacturing, assembly lines, and packaging. Our drawing provides an intricate look at the system’s simple yet effective design, showcasing how a single rotary motion is transformed into a precise 90-degree arm swing, followed by a linear vertical motion. It meticulously details the cam-follower system, linkages, and actuators that work in perfect synchrony to pick up an item from one location and place it at another with exceptional speed and accuracy. This resource is perfect for educational purposes, for use as a reference during prototyping, or to inspire your next design project. Its robust simplicity and reliability make it a timeless piece of mechanical engineering.

Key Features:

- Simultaneous Motion: The design provides a clear illustration of how a single input rotation simultaneously drives both the angular swing and the vertical lift of the arm, maximizing efficiency.

- Cam-Driven Precision: A key feature is the cam and follower system that dictates the exact motion profile, ensuring smooth acceleration and deceleration of the arm to prevent component damage.

- Compact Footprint: The mechanism’s elegant design allows for a small form factor, making it ideal for integration into crowded production lines where space is a premium.

- High Repeatability: Engineered for durability and consistent performance, this mechanism provides a high degree of positional repeatability, crucial for precision assembly tasks.

- Versatile End-Effector: The arm’s design allows for the easy attachment of various grippers or suction cups, enabling it to handle a wide range of components from small chips to larger parts.