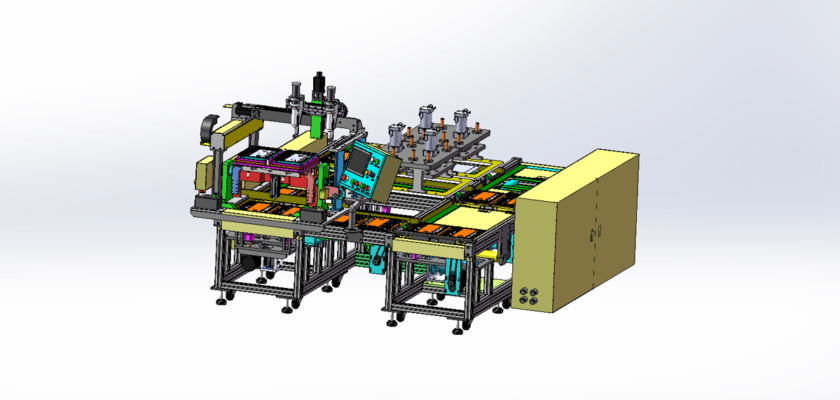

This detailed drawing of the Tablet Computer Shell Glue Dispensing Hot Capacity Production Line showcases a sophisticated system engineered for the high-volume application of adhesives in the assembly of tablet computer shells. Designed for maximum efficiency and precision, this production line is ideal for the electronics manufacturing industry.

Key Features of the Drawing:

- High-Capacity Dispensing System: The line is equipped with advanced hot melt adhesive dispensing technology, enabling rapid and consistent application to meet high production demands.

- Integrated Automation: Features automated loading and unloading processes, minimizing manual intervention and significantly increasing throughput while maintaining quality standards.

- Precision Control Mechanisms: Equipped with advanced sensors and programmable controls, ensuring accurate adhesive application and optimal bonding for various shell materials.

- User-Friendly Interface: The intuitive control panel allows for easy programming and adjustments, facilitating quick changes for different tablet models and adhesive formulations.

- Versatile Application Capabilities: Designed to handle a variety of substrates, including plastics and metals, making it adaptable for diverse tablet shell designs.

- Robust and Durable Construction: Built with high-quality materials, the production line is engineered for reliability and longevity, ensuring sustained performance in demanding industrial environments.

This drawing serves as a vital resource for engineers and manufacturers seeking to implement effective and efficient glue dispensing solutions in the production of tablet computer shells.