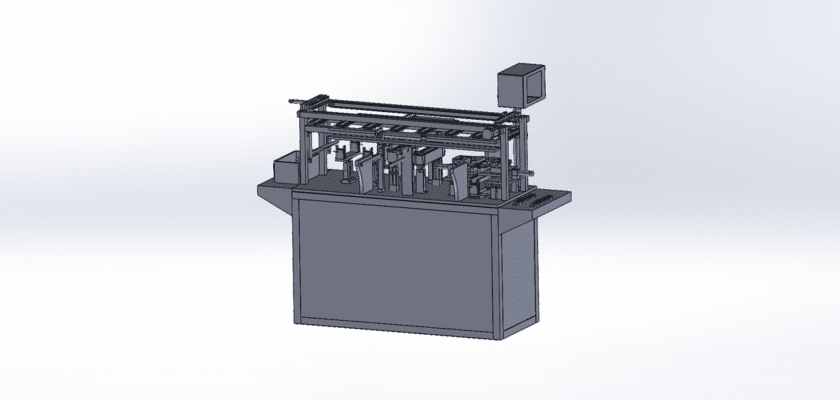

Discover the inner workings of a Test Tinning Machine with our free, downloadable drawing. This indispensable resource is a must-have for engineers, technicians, and students in the electronics manufacturing and quality control fields. A test tinning machine is a critical piece of equipment used to automatically apply a thin, uniform layer of solder (tin) to the test probes or contact points on a circuit board. This process, known as tinning, ensures reliable electrical contact and enhances the longevity of the probes during rigorous testing cycles. Our drawing provides a detailed look at the machine’s design, from the precise robotic arm that positions the test fixture to the automated solder pot and wiping mechanism. Understanding the mechanics of this machine is crucial for optimizing PCB (Printed Circuit Board) testing processes and improving product reliability. The document serves as an excellent reference for academic projects, professional design, or troubleshooting existing equipment. Its automated nature significantly reduces manual labor and ensures consistent, high-quality results.

Key Features:

- Automated Tinning Process: The design details a system that automates the precise application of a solder layer, ensuring uniformity and eliminating the inconsistencies of manual tinning.

- Robotic Arm Precision: The drawing illustrates a programmable robotic arm that accurately dips the test probes into the molten solder, ensuring all points are tinned to the correct depth.

- Integrated Solder Pot: The machine is equipped with a heated solder pot that maintains the solder at a precise temperature, as well as an automatic feeding system to ensure a constant supply.

- Controlled Dwell Time: The system is engineered to control the duration that the probes remain in the solder, which is a critical factor for achieving a proper tinning layer without causing damage.

- Wiping and Cleaning Mechanism: The drawing shows an integrated wiping system that removes excess solder from the probes, preventing bridging and ensuring a clean, perfect finish for reliable electrical contact.