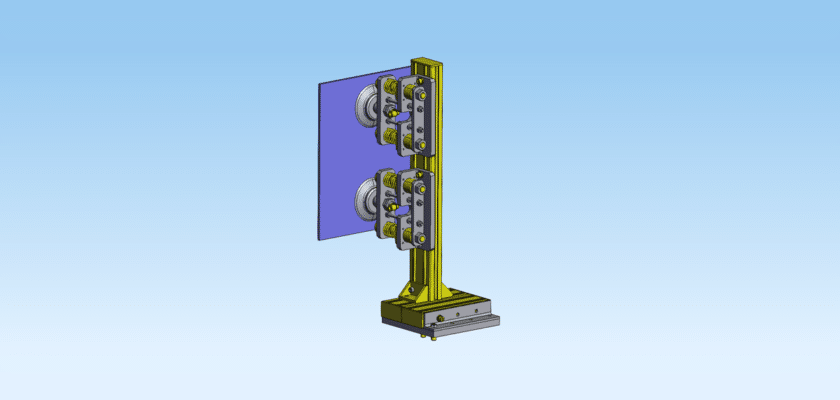

The automated transport of thin, large-surface-area materials requires a delicate balance of speed and stability. This Thin Plate Conveying Robot CAD drawing provides a high-end engineering blueprint for a specialized handling system designed to move thin metal sheets, glass panels, or PCB substrates. Traditional conveyor belts can often cause surface scratches or misalignment; however, this robotic solution utilizes a multi-axis arm or gantry system equipped with specialized end-effectors to ensure that plates are lifted and placed with sub-millimeter precision.

By downloading this professional drawing, you gain access to a structural design optimized for low-vibration motion and high repeatability. The assembly features a lightweight but rigid arm geometry that minimizes inertia, allowing for rapid cycle times without compromising the safety of the fragile payload. The technical documentation includes detailed schematics for the drive joints, the frame support, and the vacuum or magnetic gripping interface. Whether you are designing a clean-room loading system for semiconductor wafers or a heavy-duty feeder for automotive body panels, this CAD resource provides the foundational engineering required for a modern, high-speed production environment.

Key Features:

- High-Stability End-Effector: Features a distributed vacuum suction cup array or magnetic grippers designed to support thin plates uniformly, preventing sagging or deformation during transit.

- Low-Inertia Linkage Design: The robotic arms are engineered using high-strength aluminum or composite materials to maximize acceleration while maintaining structural rigidity.

- Precision Servomotor Mounting: Detailed interface plates for high-resolution motors ensure smooth, jitter-free movement across the entire workspace.

- Integrated Cable Management: Includes a dedicated internal or external “energy chain” path to protect vacuum lines and electrical cables from fatigue and interference.

- Modular Reach and Payload: The structural design is easily scalable, allowing engineers to adjust the arm length or gantry width to suit specific factory floor layouts.