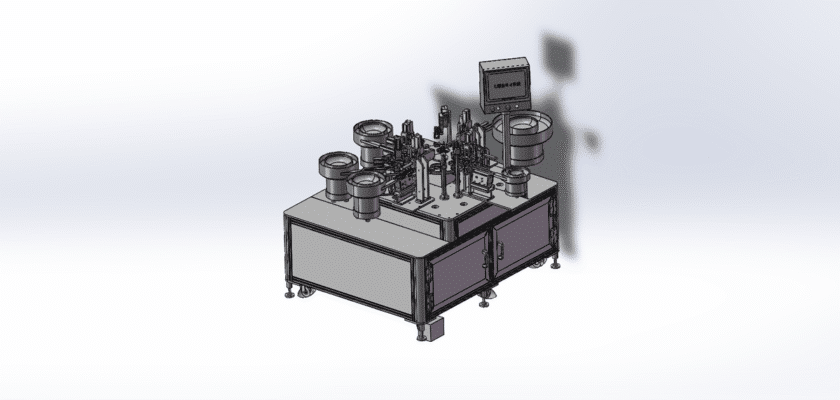

Optimize your assembly line and streamline your workflow with our free Turntable Machine drawing. This detailed CAD model provides a comprehensive blueprint for a versatile piece of equipment essential for automated manufacturing, packaging, and material handling systems. A turntable machine, also known as a rotary table, is designed to rotate products or components to various workstations, allowing for sequential processing, assembly, and inspection.

This professional drawing is an invaluable resource for engineers, students, and DIY builders who want to understand the design principles of automated rotary systems. It showcases a robust and flexible design that can be integrated into new or existing production lines to increase efficiency and reduce manual labor. By automating the movement of items, a turntable machine minimizes bottlenecks and ensures a continuous flow of products, making it a critical component for achieving high-volume production. Download this drawing to explore a powerful solution that can enhance your manufacturing capabilities and improve overall productivity.

Key Features:

- Efficient Rotary Movement: The design features a smooth, continuous or indexed rotation system that precisely positions parts for subsequent operations, such as welding, painting, or robotic assembly.

- Seamless Integration: The turntable is engineered for easy integration with conveyor belts, robotic arms, and other automated systems, providing a flexible solution for complex manufacturing environments.

- Versatile Applications: The drawing illustrates a design that can be adapted for a wide variety of industries, including automotive, electronics, food packaging, and logistics, to handle different types of products and components.

- Durable Construction: Built for industrial environments, the machine’s robust frame and heavy-duty bearing system are designed to withstand continuous operation and heavy loads, ensuring long-term reliability and minimal maintenance.

- Space-Saving Design: A turntable can effectively manage product flow in a limited space by changing the direction of the production line or creating a circular assembly cell, which is ideal for factories with floor space constraints.