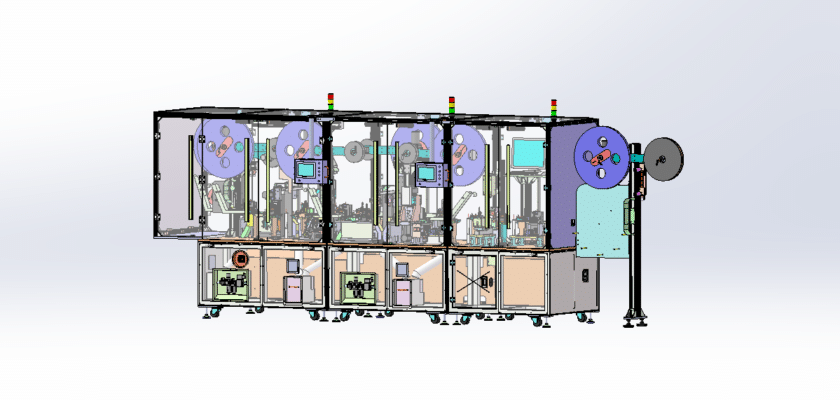

This drawing illustrates the USB Fully Automatic Assembly Machine, designed for high-efficiency production of USB connectors and related components. The machine features a modular design that allows for easy integration into existing assembly lines.

Key Features:

- Automated Operation: The machine utilizes advanced robotics for precise handling and assembly of USB components, ensuring consistency and reducing labor costs.

- Multi-Station Configuration: Equipped with multiple assembly stations, the machine can perform tasks such as component insertion, soldering, and quality inspection in a streamlined sequence.

- High Throughput: Capable of processing large volumes, the machine significantly increases production rates while maintaining high quality.

- User-Friendly Interface: An intuitive control panel enables operators to easily monitor and adjust settings, ensuring optimal performance.

- Safety Features: Integrated safety mechanisms protect operators and equipment, including emergency stop buttons and safety guards.

- Compact Design: The efficient layout maximizes floor space, making it suitable for various manufacturing environments.

This drawing serves as a comprehensive guide for understanding the machine’s assembly, operation, and integration into a production setting.