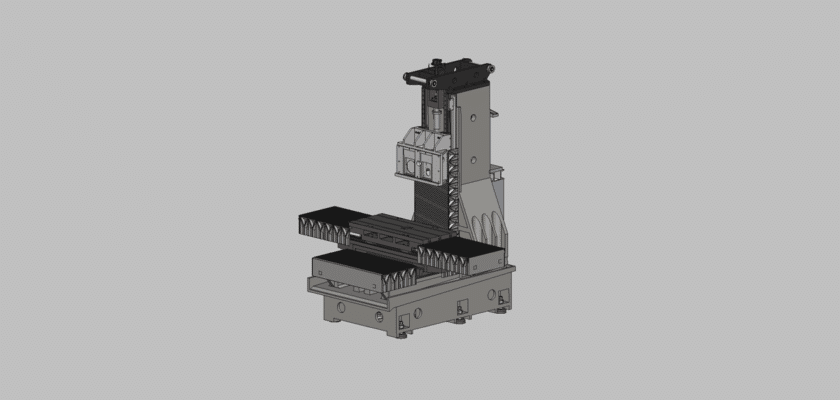

The foundation of any high-precision vertical machining center is its base, and this V65 Machine Bed drawing provides the structural blueprint for a platform engineered for maximum stability. The V65 series is known for its mid-to-large capacity, and its bed must be capable of supporting heavy workpieces while neutralizing the immense dynamic forces generated during high-speed milling. This technical drawing details a heavy-duty cast iron structure designed with internal ribbing and optimized mass distribution to minimize thermal expansion and dampen mechanical vibrations.

This technical document covers the precision-machined mounting surfaces for linear guideways, the integrated coolant drainage channels, and the reinforced leveling bolt locations. By downloading this blueprint, you gain access to a design that prioritizes geometric alignment and long-term structural integrity. The layout is optimized to handle high-load capacities on the Y-axis while maintaining the rigidity necessary for micron-level positioning. Whether you are developing a custom CNC frame or performing a structural analysis for a machine rebuild, this resource provides the verified tolerances and material specifications (such as Mehanite cast iron standards) required for a world-class machine tool foundation.

Utilize this industry-standard reference to understand the assembly of the chip evacuation slopes and the foundation anchoring points. At MechStream, we provide the blueprints that serve as the literal bedrock of modern manufacturing. Download this high-fidelity technical asset today.

Key Features:

- Advanced Ribbed Casting Design: Features an internal “honeycomb” or “box” ribbing structure to provide maximum torsional rigidity and vibration absorption.

- Precision Guideway Mounting: Detailed specifications for the scraped or ground surfaces required for ultra-precise linear rail installation.

- Integrated Chip and Coolant Management: Engineered with steep internal slopes to ensure rapid evacuation of waste material into the conveyor system.

- Thermal Stability Optimization: Designed with symmetric cross-sections to ensure uniform thermal expansion, reducing dimensional drift during long shifts.

- Heavy-Duty Anchor Points: Provides exact coordinates for foundation bolts and leveling pads to ensure the machine remains perfectly level under heavy loads.