Unleash the power of quality control with this professional Online Weighing And Rejection System drawing. This essential resource is a must-have for engineers, manufacturers, and technicians in industries like food and beverage, pharmaceuticals, and logistics. An online weighing and rejection system is a critical piece of equipment that automatically checks the weight of every product as it moves along a production line. Products that are underweight or overweight are instantly identified and automatically removed from the line, ensuring that every product meets specified weight requirements. This process is crucial for maintaining consistent product quality, complying with regulations, and preventing product waste.

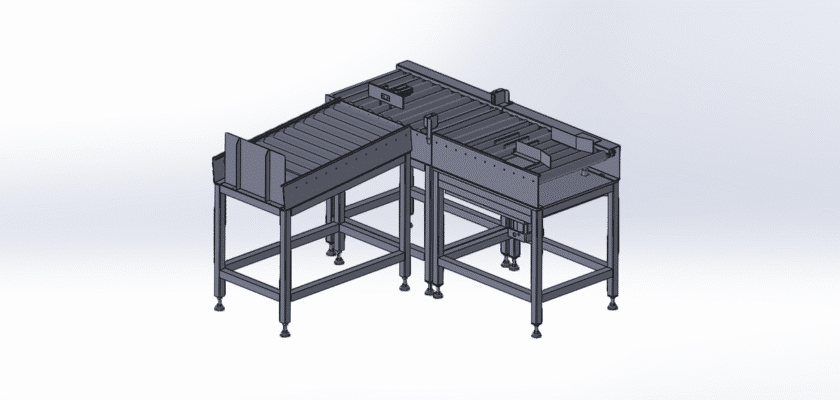

The drawing set provides an in-depth look into the system’s intricate design, including the high-speed checkweigher, the conveyor belts, and the rejection mechanism. It offers an invaluable tool for understanding the core engineering principles behind automated inspection and quality assurance. By studying these plans, you will gain the knowledge required to design your own quality control systems, optimize an existing production line, or simply deepen your understanding of modern manufacturing processes. This free download is a powerful opportunity to acquire the technical foundation needed to achieve superior quality, efficiency, and regulatory compliance in your operations.

Key Features:

- High-Speed Operation: The blueprint highlights a design engineered for rapid weighing and sorting, allowing for continuous, high-volume production without slowing the line.

- Precision Weighing: The drawing details a system with high-accuracy load cells that can measure product weight with pinpoint precision, which is critical for meeting strict weight tolerances.

- Automated Rejection: The design showcases an automated rejection arm or diverter that instantly removes out-of-spec products from the line, ensuring only compliant items proceed.

- Integrated Workflow: The plans are engineered for seamless integration into existing conveyor systems, making it a versatile and easy-to-implement quality control solution.