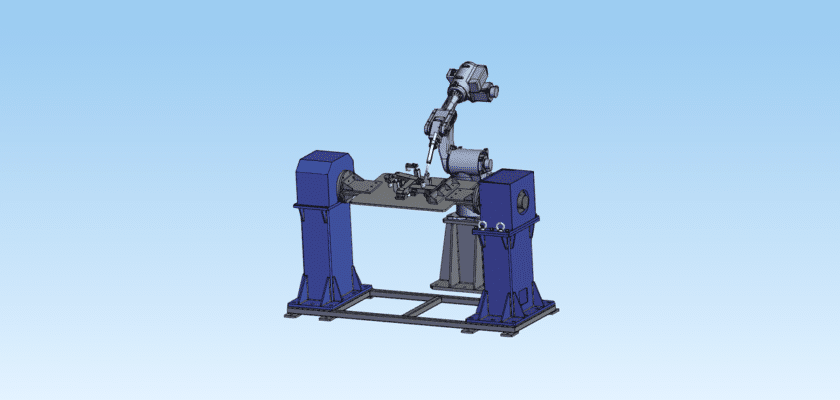

Maximize your fabrication efficiency and weld quality with our essential, free drawing package for the Welding Positioner! A welding positioner is arguably the most crucial tool in any modern fabrication shop, serving to securely clamp and precisely manipulate workpieces. Its primary function is to rotate and/or tilt the assembly, ensuring that all welding is performed in the ergonomically and technically superior ‘down-hand’ (flat) position. This not only significantly improves weld consistency and penetration but also dramatically reduces welder fatigue and risk of injury.

This comprehensive technical drawing set provides the detailed blueprints for common positioner types, including rotary tables and two-axis (tilt and rotate) units. The plans cover the robust frame design, the gearing and drive systems (for motorized units), the necessary bearing assemblies for smooth motion, and the crucial electrical grounding components. Fabricators, mechanical engineers, and technical students will find these accurate, industry-standard drawings essential for understanding, designing, or integrating custom handling solutions into their welding bays. Stop struggling with manual re-positioning or overhead welds. By downloading this critical design asset today, you gain the foundational technical knowledge to build or specify a piece of equipment that will fundamentally upgrade your entire welding workflow. Secure your free positioner drawing now and unlock superior fabrication performance!

Key Features:

- Rotational Drive Mechanism: Detailed schematics of the motor, gearbox, and control interface for precise, controlled 360-degree rotation of the faceplate.

- Tilting Axis Capability: Blueprints illustrating the mechanical locking or motorized system that allows the table to be angled, ensuring optimal weld access.

- T-Slotted Faceplate Design: Drawings specifying the dimensions and layout of the work table for easily and securely mounting diverse jigs and fixtures.

- Integrated Grounding System: Details of the dedicated electrical pathways and contacts used to provide a reliable return path for the welding current through the positioner body.

- Load Capacity Specifications: Schematics highlighting the structural design and bearing selection necessary to safely handle various specified workpiece weights and cantilevered loads.