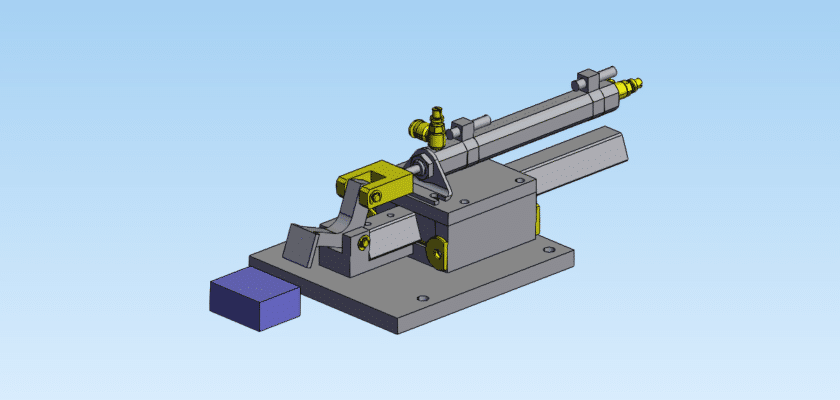

In the fields of stamping, molding, and forming, the ability to safely and consistently remove a finished part from a die or cavity is as important as the forming process itself. This Workpiece Extrusion Device CAD drawing provides a high-performance blueprint for an ejection or pushing mechanism designed to handle high-force applications. Whether you are dealing with friction-fitted parts in a cold-forging die or delicate plastic components in an injection mold, this device is engineered to apply uniform pressure, ensuring the workpiece is discharged without deformation or surface marking.

By downloading this professional drawing, you receive a comprehensive look at a mechanical assembly designed for high durability and repeatability. The design features a guided plunger or plate system that can be actuated via pneumatic cylinders, hydraulic rams, or mechanical cam followers. By integrating this extrusion device into your automated cell, you minimize cycle times and eliminate the need for manual intervention, significantly boosting overall production efficiency. The technical documentation includes critical tolerances for the sliding components and material recommendations for high-wear areas, ensuring your built device can withstand the rigors of continuous industrial operation.

Key Features:

- Uniform Force Distribution: Features a balanced pusher plate or multi-pin layout to prevent localized stress and ensure the workpiece is pushed out evenly.

- Precision Linear Guidance: Utilizes hardened guide bushings and pillars to maintain perfect alignment, preventing the extrusion head from tilting or jamming under load.

- Adjustable Stroke Control: Includes mechanical limiters or sensor mounting points to allow for precise adjustment of the ejection travel distance.

- High-Strength Return System: Equipped with heavy-duty die springs or dual-action pneumatic ports to ensure the extrusion head resets quickly for the next cycle.

- Wear-Resistant Contact Surfaces: Specifications include heat-treated tool steel or specialized coatings for the parts in direct contact with the workpiece to maximize service life.