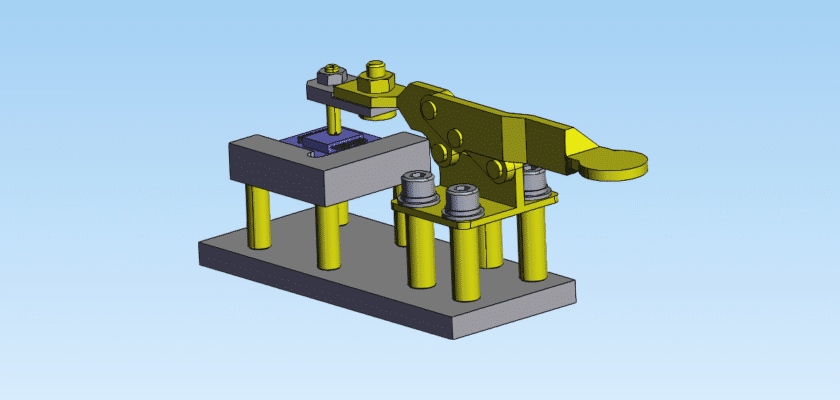

In precision manufacturing, a part that isn’t accurately positioned cannot be accurately machined. This Workpiece Positioning and Clamping drawing provides the comprehensive technical framework for the 3-2-1 principle of fixture design. Positioning and clamping are two distinct but inseparable functions: positioning ensures the part is located correctly relative to the machine’s coordinate system, while clamping ensures it stays there under the influence of cutting forces. This blueprint details a integrated system that eliminates the six degrees of freedom of a workpiece, providing a rock-solid foundation for high-tolerance CNC milling, drilling, and inspection.

This technical document covers the assembly of primary, secondary, and tertiary locating datums, alongside synchronized clamping units. By downloading this drawing, you gain access to a design that prioritizes “repeatability”—the ability to load and unload parts with micron-level consistency. The layout includes specifications for diamond and round locating pins, adjustable supports to prevent part deflection, and high-force clamping mechanisms that apply pressure directly over the support points to avoid part distortion. Whether you are designing a dedicated production fixture or a modular prototype setup, this resource provides the verified mechanical data and geometric tolerances required for professional-grade workholding.

Stop relying on guesswork and makeshift setups. Use this industry-standard reference to understand how to balance clamping force against positioning accuracy to avoid “part walk” or surface marring. At MechStream, we provide the blueprints that ensure your first part is as accurate as your thousandth. Download this essential technical asset today.

Key Features:

- Strict 3-2-1 Locating Logic: Detailed schematics for establishing primary, secondary, and tertiary datums to fully constrain the workpiece.

- Anti-Deflection Support Layout: Includes specifications for adjustable and fixed supports located directly beneath clamping points to prevent part bending.

- Error-Proofing (Poka-Yoke) Integration: Designed with asymmetrical pin layouts or interference blocks to prevent the operator from loading the part incorrectly.

- Coordinated Clamping Forces: Engineering data for ensuring that clamping vectors are directed toward the locators, preventing the part from lifting during the cycle.

- Hardened Contact Surfaces: Features callouts for D2 or O1 tool steel locators and jaw faces to ensure long-term wear resistance and accuracy.