Unlock precision in gear manufacturing with our Gear Dimension Calculator. This intuitive tool is designed for engineers and machinists to accurately calculate key parameters such as pitch diameter, module, and number of teeth. Enhance your design efficiency and ensure flawless gear performance with precise dimensions. Our calculator facilitates quick computations, minimizing errors and saving valuable time in the design process. Whether you’re designing gears for industrial machinery or custom projects, this tool is your go-to resource for optimum results. Experience seamless calculations and elevate your gear craftsmanship with our user-friendly interface today.

Parameters

The basic unit of gear size, representing the ratio of pitch diameter to number of teeth. Standard values: 0.5, 0.8, 1, 1.25, 1.5, 2, 2.5, 3, 4, 5, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50 mm.

The total number of teeth on the gear. Must be a positive integer.

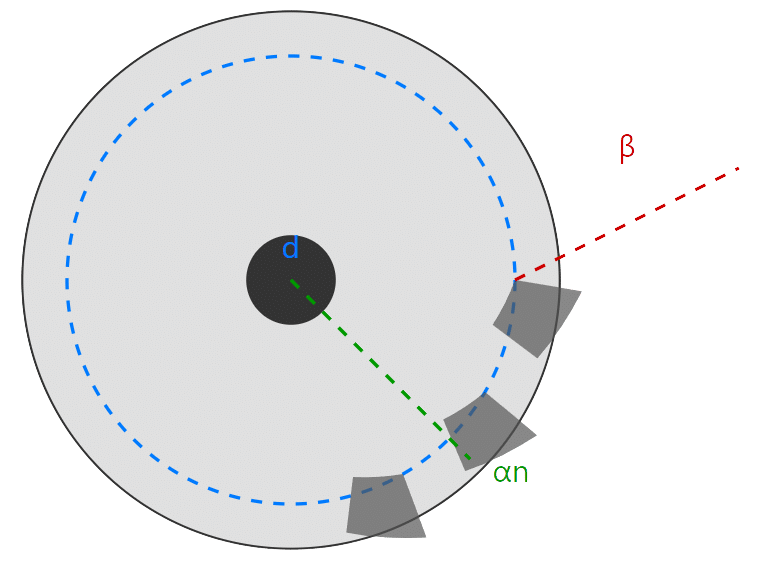

The angle between the line of action and the tangent to the pitch circle. Standard values: 20° or 25°.

The amount of profile shift applied to the gear teeth. Typical range: -0.5 to +0.5.

Standard value is 1.0 for normal gears.

Standard value is 1.25 for normal gears.

The number of teeth spanned when measuring the span (normal chordal) thickness of a gear tooth.

The angle between the tooth flank and the gear axis on the pitch cylinder. For helical gears.